About the Agricultural School Building Project

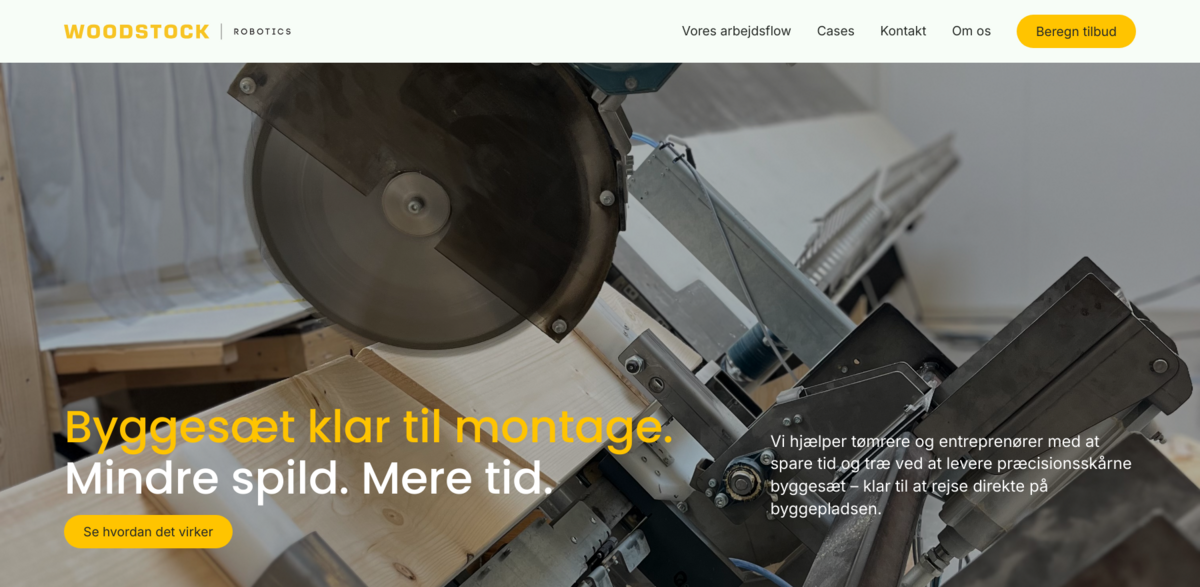

The project involved constructing a 700m² agricultural school spread over two floors, completed at record speed using precision-cut, prefabricated building kits. These kits were delivered ready for assembly directly on site, eliminating delays and minimizing waste. The approach focused on delivering a smart, efficient wood construction solution that supports carpenters and contractors by saving both time and materials.

Main Benefits of Using Precision-Cut Building Kits

This innovative method brought several advantages to the construction process, including:

- Material waste kept impressively low at just 4.8% across more than 8 kilometers of construction wood

- Efficient transport with only a few loads, delivered straight to the assembly location

- Total wood length used: 8,066 running meters, covering five different cross-section dimensions

- Zero waiting time during construction, as elements were mounted immediately upon delivery

- Almost no construction waste generated on site

- Improved working environment with no heavy lifting and optimal workflow

- Precise packing logic and ID marking ensured smooth handling and assembly

From Sketch to Completed Building Kit

Wood construction has never been simpler. The process starts with a detailed sketch and ends with a fully prepared building kit, ready to be assembled on site. This seamless journey supports contractors every step of the way, making the entire build faster and more efficient. It’s a game-changer for anyone looking to streamline wood construction projects.

How Prefabricated Kits Reduce Waste and Save Time

By delivering building kits that are precision-cut and ready for assembly, the project drastically cut down on material waste and construction delays. The careful planning and execution meant that wood was used optimally, and the construction site remained clean and organized. This approach not only saves money but also contributes to a more sustainable building process.

A Smarter Way to Build Larger Wood Constructions

When speed is crucial and space is limited, prefabricated building kits from Woodstock Robotics offer a powerful solution. They excel in price, environmental impact, and execution quality. This method is especially suited for institutional and commercial buildings where efficiency and minimal disruption are key priorities.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure – promoting innovative construction techniques

- SDG 11: Sustainable Cities and Communities – supporting sustainable building practices

- SDG 12: Responsible Consumption and Production – minimizing waste through precision cutting

- SDG 13: Climate Action – reducing environmental impact by optimizing material use and transport

Contact and Opening Hours

For those interested in optimizing institutional or commercial building projects, assessments are available to explore how this approach can be tailored to specific needs. The office is open Monday to Friday, from 09:00 to 17:00. For inquiries, the contact number is +45 71 71 08 08.