What is the IPSIIS Project?

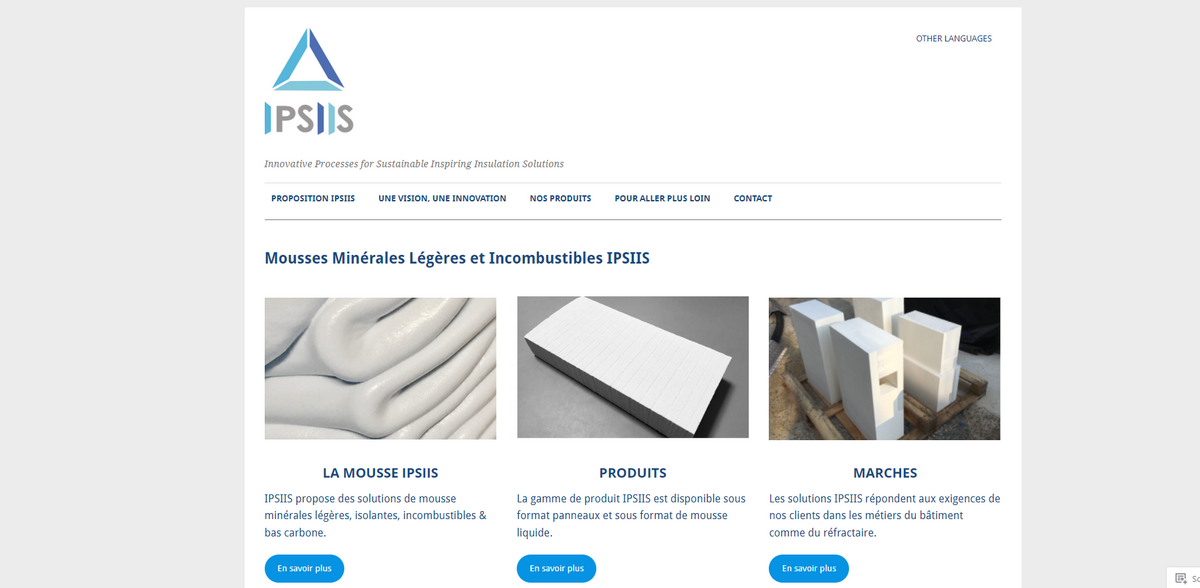

IPSIIS is an innovative project that develops noncombustible, insulating, and refractory mineral foams. The project focuses on creating lightweight, non-combustible mineral foam solutions that are both insulating and low carbon. Available in panel format and liquid foam format, the IPSIIS product range is designed to meet the stringent requirements of clients in the construction and refractory sectors. The concept is simple yet dynamic: use selected mineral powders, natural additives, and water to produce a mineral plastic foam with exceptional cohesion and strength… all while keeping the environmental footprint as low as possible.

Main Benefits of IPSIIS

The benefits of IPSIIS are not only technical but also economic and environmental. Key figures and facts include:

- Utilizes mineral powders that can represent up to 90% of the total mass of the final product.

- Can valorize mineral waste up to 85% in the formulation.

- Recognized as an Efficient Solution by the Solar Impulse Foundation in 2018.

- Offers lightweight, low-carbon, – and noncombustible – alternatives in insulation solutions.

- Customizable panel and liquid foam formats tailored to client requirements in both construction and refractory industries.

Innovative Processes for Sustainable Insulation Solutions

IPSIIS proposes a unique manufacturing process which remains robust yet simple enough to be easily adapted into existing industrial activities. The approach centers around using local resources to keep investment and capital expenditure (CAPEX) low while still achieving high energy efficiency. Natural additives and water are mixed with carefully selected mineral powders to ensure the production of a mineral plastic foam that offers both remarkable strength and thermal insulation properties. This method enriches sustainable construction solutions in a circular economy logic.

Focus on Non-Combustible Mineral Foams

Refractory mineral foams are at the core of IPSIIS’s offering. The product is designed to address high temperature insulation needs particularly in industrial settings, while also providing acoustic and temperature insulation in building applications. The noncombustible characteristic of these mineral foams brings an added level of safety, ensuring protection of people and goods against potential fire hazards. The process is low in risk and environmentally sound, which means the production can be easily integrated into dedicated local operations without raising major environmental concerns… a practical solution that stands out in progressive construction and insulation markets.

Eco-Friendly Manufacturing and Local Impact

The manufacturing process behind IPSIIS mineral foams is characterized by its low capital intensity and flexible integration into existing production lines. By selecting mineral powders based on specific client requirements and mixing them with natural additives and water, the result is a resilient mineral plastic foam that not only insulates but also supports sustainable practices. The use of up to 90% mineral content and the possibility to include up to 85% recycled mineral waste exemplify a commitment to environmental sustainability. In addition, the project’s ethos of using local resources helps bolster local economies and supports local manufacturing, marking an important step towards reducing overall environmental impacts.

Project Impact on Sustainable Development Goals

- SDG 7: Affordable and Clean Energy – Enhances energy efficiency in building insulation.

- SDG 9: Industry, Innovation, and Infrastructure – Promotes innovative, low-capital-intensive production processes.

- SDG 11: Sustainable Cities and Communities – Contributes to heat and acoustic insulation in urban structures.

- SDG 12: Responsible Consumption and Production – Emphasizes the valorization of recycled materials and responsible use of resources.

- SDG 13: Climate Action – Focuses on reducing carbon content in building materials.

Future Outlook: Enhancing Construction Sustainability

Looking ahead, IPSIIS represents a significant advancement in the construction and refractory sectors. Its innovative approach towards producing noncombustible insulating materials with very low carbon impact is paving the way for safer, more sustainable, and energy-efficient building solutions. The IPSIIS product, available both as panels and as liquid foam, offers a versatile solution that can be expertly adapted to high temperature insulation in industries as well as for building purposes where both acoustic and thermal properties are crucial. Such progress demonstrates that low CAPEX manufacturing – coupled with the safe and integrated production processes – is fully capable of supporting local economic development while simultaneously adhering to modern environmental and safety standards.