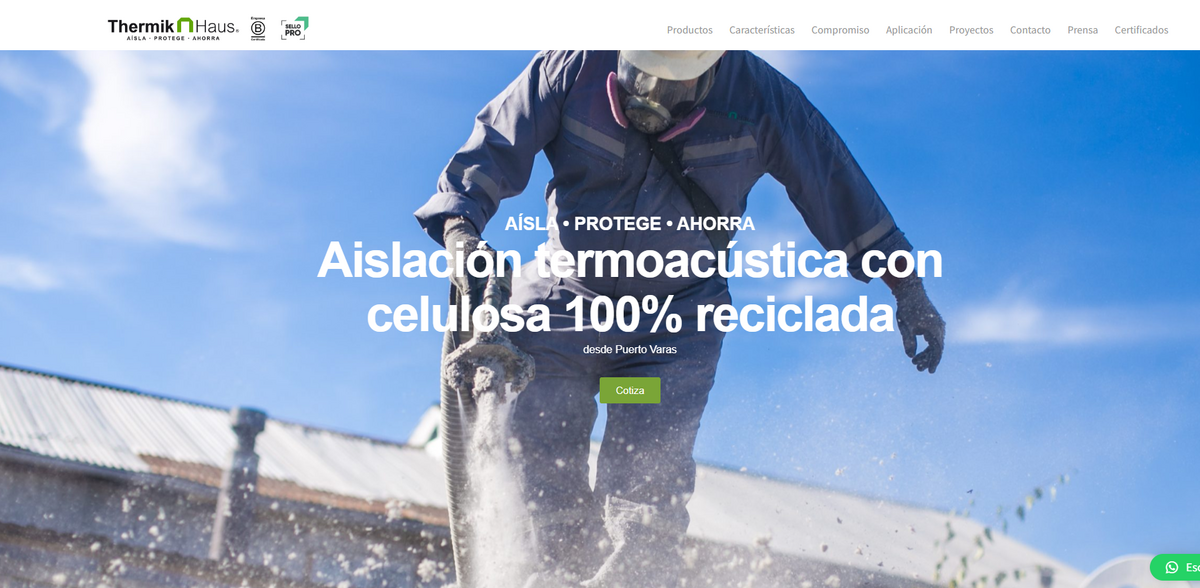

What This Project Is

This project offers a unique service for thermal and acoustic insulation with 100% recycled cellulose, proudly originating from Puerto Varas. Designed for the construction and architecture industry, its core components include recycled cellulose insulation that adheres to modern standards of sustainability, efficiency, and safety in construction. The service package covers labor, transportation of raw materials, installation, and on-site waste management. Additionally, specialized products, such as the recycled cellulose insulation, waterproof membranes, and even machinery rentals for self-installation, underscore an impressive balance between advanced technology and environmentally responsible practices.

Main Benefits and Key Figures

Key figures and facts of this project showcase numerous advantages:

- Cost of insulation: $8,000 per m² – a competitive value influenced by the project type, installation method, and local conditions.

- Recycled cellulose composition: Approximately 85% recycled paper/cardboard and 15% borax, contributing significantly to sustainability.

- Product weight and yield: Each cube is around 16 kg and offers an approximate yield of 30 kg/m³, making it an efficient choice for insulation needs.

- Waterproof membrane Blockit: Manufactured in the USA; it is priced at $1,200 per m², lending exceptional protection while allowing breathability.

- Daily machine rental: Starting at $120,000 CLP for a minimum of three days, allowing for self-installation which can save up to 40% on insulation costs.

The Innovation Behind Installation Methods

Innovation is at the heart of these insulation applications. The project employs three main types of installation: projected, injected or insulated, and loose dry or bulk. Each method is designed for different construction needs – be it roof, walls, or floors. With an impressive progress rate of up to 150 m² per day per machine, the process is fast and efficient. The cellulose is projected in a continuous blanket, completely covering the surface and reducing any risk of thermal or acoustic bridges… ensuring both energy efficiency and peace of mind.

Sustainable Materials and Environmental Impact

The project presents an eco-friendly solution where at least 85% of the raw material originates from recycled sources, significantly reducing the overall carbon footprint. The materials used, like recycled cellulose, not only prove effective against heat and sound transmission but also contribute to a cleaner, more sustainable construction process. Moreover, the inclusion of borax not only lends fire resistance but also deters pests, proving this solution to be both safe and environmentally thoughtful. Its design is consistently aligned with principles of sostenibilidad and reciclaje, ensuring that nearly every aspect of the operations reinforces a commitment to the planet.

Certifications, Value, and Additional Benefits

In addition to its technical merits, this project boasts multiple certifications that validate its claims to safety and sustainability. Recognition as a B Corporation and the Pro Seal awarded by the Chilean Construction Chamber are clear indicators of the company’s dedication. Fundamentally, the insulation not only aids in thermal regulation and acoustic control but also prevents condensation, repels pests, and is non-toxic. These elements add up to a solution that powers both construction innovations and community well-being. This approach reinforces a value system based on ethical principles where integrity, transparency, and commitment to the environment are prioritized.

Project Impact

- SDG 7 – Affordable and Clean Energy: Through improved thermal insulation, energy savings are maximized.

- SDG 11 – Sustainable Cities and Communities: Fast, efficient installations contribute to better urban living spaces.

- SDG 12 – Responsible Consumption and Production: The project leverages high percentages of recycled materials to reduce waste.

- SDG 13 – Climate Action: Reduced carbon footprint through sustainable practices helps combat climate change.

- SDG 9 – Industry, Innovation, and Infrastructure: Advanced machinery and installation methods showcase state-of-the-art construction practices.

Completed Projects and Practical Applications

The insulation technology has already proven its worth across a range of settings. Completed projects include residential houses, commercial buildings, schools, restaurants, warehouses, containers, and even boats. In houses up to 140 m², the insulation has been installed in as little as two days, providing quick yet effective results. For commercial buildings and offices, the process ensures zero waste while respecting strict timelines, making it a favored choice in construction projects that demand speed and reliability. In schools and restaurants, beyond thermal benefits, acoustic damping plays a crucial role in preserving a comfortable and peaceful environment. The adaptability of the technology extends to retrofitting thermal insulation in previously built spaces, thereby improving overall energy efficiency without the need for major structural changes… rendering this solution as one of the fastest and easiest cellulose installations available.