What is Trenchless Automated Leakage Repair (TALR)?

Curapipe’s patented Trenchless Automated Leakage Repair, or TALR, is a smart, internal pipeline leakage repair solution designed specifically for tackling multiple leaks in water distribution networks. It’s especially handy when pipelines suffer from substantial leakage coming from various sources—think pinholes caused by external corrosion, lead-run cast iron joints, longitudinal cracks in PVC pipes, or even hoop stress in ferrous pipes. It also handles split bells from transverse stresses on pipe joints, circumferential breaks due to thermal contraction, displaced ‘O’ rings on PVC joints, failed welds on MDPE joints, and leaky service connections. Basically, TALR is built to handle a wide range of pipe materials and leak types.

Main Benefits of TALR

Here’s the lowdown on what makes TALR stand out:

- Seals a variety of leak types on both water mains and connected service pipes.

- Meets stringent health requirements for products that come into contact with drinking water.

- Rapid deployment at a low cost—quick and efficient.

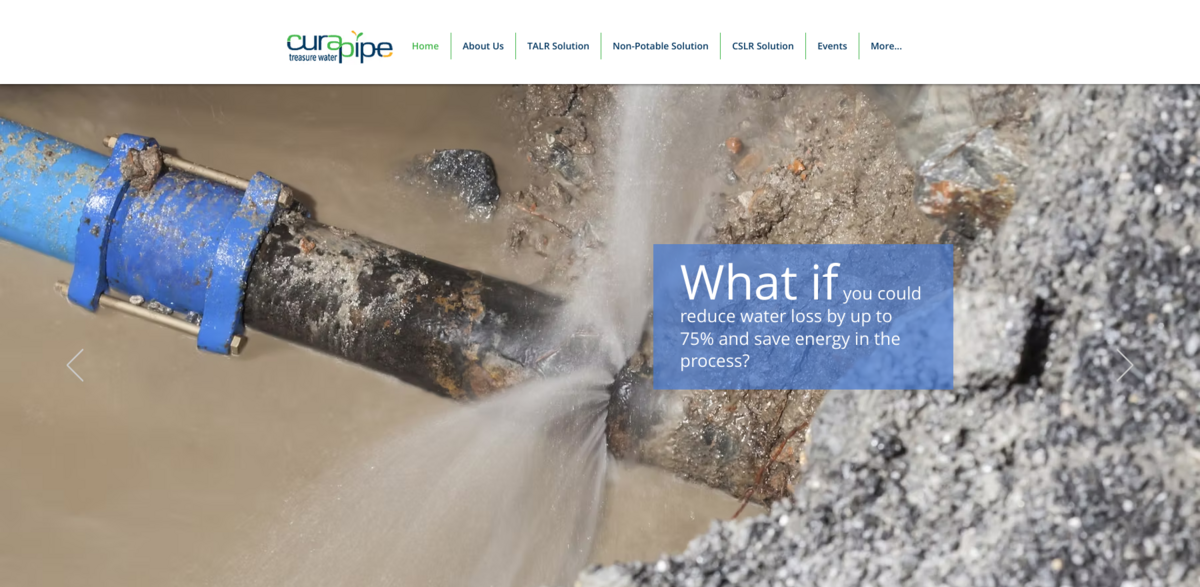

- Achieves a 75% reduction in overall leakage.

- Provides a long-term cure that lasts.

How Does TALR Work?

The process is pretty clever. First, a PIG train is launched into an isolated section of the water distribution network through an upstream fire hydrant or hot tap. This PIG train carries a compartment filled with Curapipe’s unique viscous curing substance, wedged snugly between two PIGs. Under pressure, this substance automatically detects leaks—whether pinholes, joints, fittings, or service connections—and seals them on the spot. Once the PIG train reaches the downstream fire hydrant, it’s extracted, leaving the curing substance to harden and permanently fix the leaks. It’s a one-time intervention that keeps on giving.

Why TALR Matters in Today’s Water Crisis

The world is waking up to some harsh realities. Climate change is shaking up precipitation patterns way earlier than expected, leading to more water-stressed areas and even droughts in places that used to have plenty of water. Traditional water sources like rainwater, surface water, and groundwater just aren’t enough anymore. Regulators and utilities are scrambling to keep water supplies resilient in cities, facing all this climate uncertainty. TALR offers a timely, cutting-edge solution—a one-time fix that continuously recoups a major chunk of water lost in urban distribution systems. It’s a game-changer in water conservation.

Integration with Existing Water Management Systems

TALR doesn’t work in isolation. It’s designed to complement ongoing active leakage management services, like the classic “find & fix” approach. Plus, it plays nicely with installed network pressure reduction systems, making it a versatile addition to any water utility’s toolkit. By rapidly reducing bulk leakage, TALR helps utilities focus their resources more efficiently and maintain better control over their water networks.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 6: Clean Water and Sanitation – by reducing water loss and improving water supply reliability.

- SDG 9: Industry, Innovation, and Infrastructure – through innovative pipeline repair technology.

- SDG 11: Sustainable Cities and Communities – by enhancing urban water resilience.

- SDG 13: Climate Action – by addressing water scarcity issues linked to climate change.

Looking Ahead: The Future of Water Leakage Repair

As water scarcity becomes a more pressing global issue, solutions like TALR are stepping into the spotlight. The ability to quickly and effectively seal leaks without digging up pipes means less disruption, lower costs, and a smarter way to manage precious water resources. With climate change accelerating water stress worldwide, technologies that can adapt and respond rapidly will be crucial. TALR’s trenchless, automated approach offers a glimpse into the future of sustainable water management—efficient, innovative, and ready to tackle the challenges ahead.