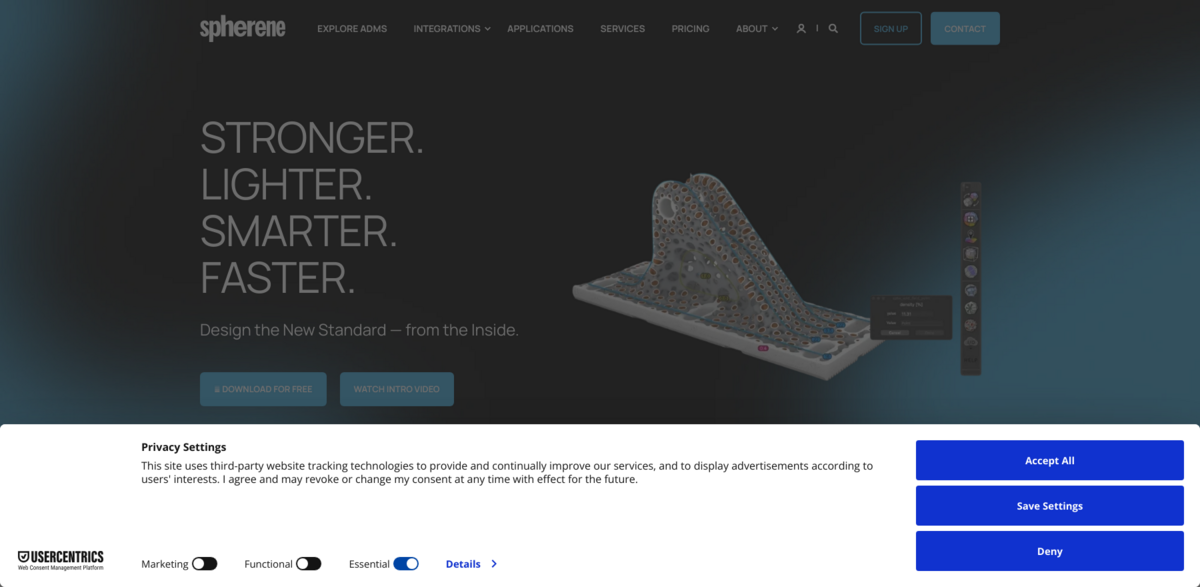

What is Spherene and Its Groundbreaking Technology?

Spherene is a Swiss software company and the pioneer of Adaptive Density Minimal Surfaces (ADMS) for the Additive Manufacturing market. In simple terms, Spherene provides software that lets engineers and designers create lighter, stronger, and more efficient parts faster by optimizing geometry at a fundamental level. Think of it as the CAD for the inside. Instead of relying on conventional lattices or repetitive infill structures, Spherene’s ADMS adapts continuously to loads, shapes, scales, and boundary conditions, making it a game-changer in design and manufacturing.

Main Benefits of Spherene’s ADMS

Here are some key points that highlight what makes Spherene stand out:

- What it does: Transforms CAD models into high-performance, 3D-print-ready structures that minimize weight while maximizing performance.

- How it works: ADMS adapts the density and surface geometry locally (unlike traditional gyroids or TPMS), enabling support-free printing and highly functional metamaterials.

- Who uses it: Aerospace, automotive, energy, medical, footwear, and construction companies seeking stronger, lighter, or more sustainable components.

- Integration: Available as plugins for CAD/CAE platforms like Rhino/Grasshopper, Autodesk Fusion, and nTop, with more integrations planned.

The Future of Lightweight, High-Performance Design

Spherene’s ADMS represents the next evolution of minimal surfaces. Unlike TPMS, which depend on repeating, grading, and trimming unit cells, ADMS adapts continuously and locally, conforming perfectly to the part’s true intent. This is a fundamentally new approach — generated uniquely for each design in a single intelligent step that considers all functional and geometric requirements simultaneously. It’s not just an upgrade; it’s a whole new class of minimal surface.

Isotropy Where It Really Matters

One of the standout features of ADMS is its near-perfect isotropy, delivering uniform mechanical performance in every direction. Unlike conventional TPMS lattices that introduce directional weaknesses, ADMS allows engineers to design with confidence — ensuring predictable behavior under complex, multi-directional loads. This means no weak points, no premature failure, just reliable strength wherever it’s needed.

Support-Free by Design

ADMS produces smooth, continuous geometries that are manufacturable with little or no supports. This translates to less material waste, shorter print times, and minimal post-processing — cutting costs while unlocking unprecedented design freedom. It’s a win-win for manufacturers and designers alike, making complex parts easier and cheaper to produce.

Impact on Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure — by advancing additive manufacturing technologies.

- SDG 12: Responsible Consumption and Production — through material efficiency and waste reduction.

- SDG 13: Climate Action — by enabling lighter, more efficient components that reduce energy consumption.

- SDG 3: Good Health and Well-being — via medical implants that promote bone integration.

ADMS vs. TPMS: A New Era in Metamaterials

Minimal surfaces have long played a role in additive manufacturing — think gyroids and other Triply Periodic Minimal Surfaces (TPMS) like Schwarz P, Diamond, or Lidinoid. But TPMS come with limitations: they rely on repeating unit cells, require trimming and patching, and often compromise performance while restricting adaptability. Spherene’s ADMS flips the script. Instead of forcing repetitive cells into complex geometries, ADMS conforms intelligently to the part’s shape and functional requirements, placing material only where it’s needed. This means smoother, continuous surfaces, near-perfect isotropy, and support-free printing. Plus, it’s fast and intuitive — complex adaptive structures can be created in minutes and tweaked in seconds. The result? A new class of metamaterials that are lighter, stronger, and smarter, redefining what’s possible in additive manufacturing.