What is Pandobac’s Reusable Crates Project?

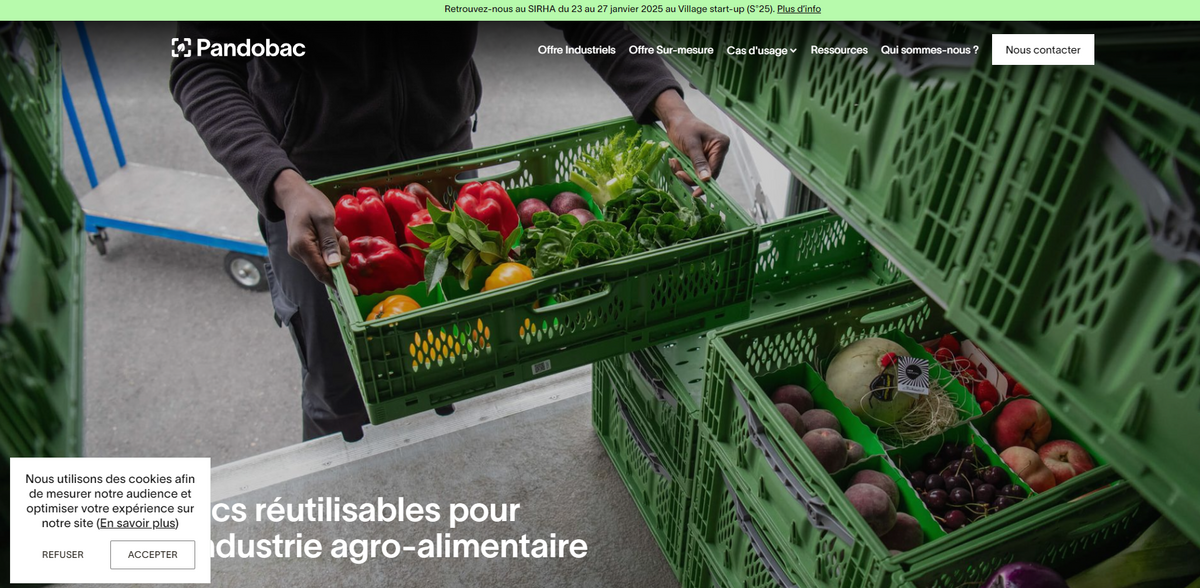

Pandobac offers an innovative packaging solution tailored for the food industry by providing a reusable industrial packaging service. This project focuses on the transport of fresh produce with an emphasis on emballages, réemploi, zéro déchet, économie circulaire, and réutilisation. It brings together an integrated system covering the rental, tracking, washing, and return logistics of reusable multi-use containers. The service is designed to support food manufacturers, RHF suppliers, collective and commercial catering, and major distributors, ensuring that every step of the logistics process is managed effectively. The solution is presented as a turnkey project with a clear structure: an initial feasibility study to comprehensively assess the operation, followed by a pilot phase that tests the most suitable container formats, and finally, full deployment with the optimal management of container flows. A seamless integration into existing distribution chains and automated lines is nurtured through personalized protocols and training sessions for all stakeholders… all while ensuring compliance with regulations such as the AGEC law.

Main Benefits and Key Figures

The reusable containers provided by Pandobac have clear advantages, displayed as key facts below:

- Compliance with reuse packaging objectives of the AGEC law.

- Improved cost control over packaging expenses, with stability against economic fluctuations.

- Positive environmental impact through significant savings in water, raw materials, and waste reduction.

- Enhanced protection of fresh products, reducing breakage and losses during transport.

- Competitive advantages by transitioning to a reuse model that aligns with modern circular economy trends.

- A strong B Corp rating of 81.2, reflecting robust social and environmental performance.

Tailored Phases and Implementation

The project is structured in three distinct yet connected phases that ensure smooth integration into current operations. The first step begins with a detailed feasibility study and impact assessment—a phase that lasts approximately three months—during which all operational challenges are identified. This step involves field diagnostics and modeling of flows and impacts, providing participants with an accurate vision of the system and the roles of every stakeholder. Following this, a six-month pilot phase is launched where predefined protocols and training sessions allow the service to be tested in real scenarios. During the pilot phase, practical learnings are gathered, technical obstacles are addressed, and modifications are made to align with production lines and logistics systems. Finally, deployment is executed by gradually scaling the reuse project, ensuring that container delivery, washing, and reverse logistics are managed efficiently while continuously monitoring performance indicators.

Flexible Container Solutions

Pandobac supports an extensive catalog of reusable containers designed to replace traditional single-use packaging such as cardboard, wooden crates, or EPS boxes. The container types vary in shape, size, and design, with options that are always stackable and, in many cases, nestable or foldable. The formats are carefully chosen to be easily palletizable on Europe pallets, making integration into existing automated lines smoother. Through field evaluations, appropriate container options are selected that best suit the transported products—whether fruits and vegetables, meat and poultry products, seafood, dairy, or bakery items—which ensures minimal breakage and maximizes overall protection. This variety in design provides significant flexibility while meeting diverse technical requirements.

Industry Collaborations and Clientele

The reach of the reusable packaging project extends across multiple facets of the food industry. Prominent manufacturers such as Bigard, Cooperl, and Bel have embraced the system by shifting towards a reuse model with Pandobac’s container solutions for their clients. Moreover, major RHF distributors like Transgourmet and France Frais have partnered in the implementation of these eco-friendly solutions, while trials with GMS (general merchandise distributors) are also in progress. This broad network of collaborations ensures that every client, regardless of size or specific sector within the food industry, can benefit from a system that enhances product safety, optimizes logistics, and promotes sustainability.

Operational Advantages and Environmental Impact

The reusable containers model significantly reduces costs associated with single-use packaging, contributing positively to both economic and environmental outcomes. By reducing dependency on disposable packaging, this approach helps lower waste production and minimizes resource consumption. Moreover, the strategic return logistics—comprising collections at mass points like distributor logistics platforms—further contribute to efficient system transactions. The tracking tool developed as part of the service ensures real-time monitoring of container usage, preventing losses and inefficiencies. Businesses appreciate this well-rounded service not only for its cost efficiency but also for its ability to support broader initiatives in circular economy and zero waste strategies. Such operational, economic, and ecological factors converge to offer an optimal solution for modern packaging challenges.

Project Impacts and Sustainability Goals

- SDG 12: Responsible Consumption and Production – Promotes the reuse of packaging and sustainable resource management.

- SDG 13: Climate Action – Reduces environmental impacts by minimizing waste and resource use.

- SDG 9: Industry, Innovation, and Infrastructure – Encourages innovative industrial solutions by integrating modern tracking tools.

- SDG 11: Sustainable Cities and Communities – Supports improved logistics and sustainable urban practices.

- SDG 8: Decent Work and Economic Growth – Enhances operational efficiencies and cost control for participating companies.

Funding Support and Future Perspectives

The reusable packaging project is made even more attractive by its eligibility for subsidies covering up to 70% of project costs. This financial support enables food industry players to reduce initial investments while embarking on a circular economy transformation. Assistance with funding extends from identifying relevant subsidies to developing grant applications and gathering the necessary documentation for fund release. This level of support reinforces the commitment to not only achieving better cost efficiencies but also contributing to a vibrant, sustainable future with reduced waste. The initiative remains a model example of how advanced logistics and mindful packaging choices can intersect to yield economic advantages and a reduced environmental footprint—all of which are essential steps toward a zero waste, circular economy future.