What the Project Is

Nanolayers is proud to continue its collaboration with Neil Curson and UCL on the EPSRC funded project Dopant-based Quantum Technologies in Silicon. The initiative builds on previous work towards building automated atomic lithography capabilities and a suite of machine learning tools developed during the Innovate UK funded ALANN project. This project, along with additional efforts, bridges the gap between academic physics and real-world products, reflecting the organization’s commitment to turning laboratory breakthroughs into industrial-scale applications… The narrative involves collaborations spanning multiple prestigious institutions and highlights an ongoing endeavor to integrate advanced atomistic precision with modern fabrication techniques.

Main Benefit

- Building automated atomic lithography capabilities.

- Development of machine learning tools for upscaling fabrication techniques.

- Collaboration on an EPSRC funded project with UCL and Neil Curson.

- Achieving working hydrogen storage capacity improvements: 10 wt.% and 44 g H2/l at low compression.

- Targeting a storage increase to at least 40 g H2/l to advance hydrogen-powered vehicle technology.

- A substantial investment in innovation with a Horizon project budget of 4,638,414.00 €.

- Partnership with thirteen partners across eight countries to push Europe’s decarbonization agenda.

Dopant-based Quantum Technologies and ALANN Project

The collaboration on the EPSRC funded Dopant-based Quantum Technologies in Silicon project is built on a solid foundation. Nanolayers has already demonstrated its expertise in automated atomic lithography as part of its previous engagement in the Innovate UK funded ALANN project. It is through these achievements that the project continues to push boundaries, leveraging state-of-the-art machine learning tools to enhance fabrication techniques. The approach is not only technically rigorous but also pragmatically aligned with industrial applications… capturing the spirit of innovation driven by the intersection of quantum technology and advanced manufacturing.

Intelligent Materials Informatics Platform

Nanolayers announced its collaboration with NanoAcademic Technologies in the UK-Canada iUK/NSERC joint project iMAT-CM. This project focuses on developing an intelligent materials informatics platform for critical minerals, ensuring their sustainable use and replacement. The partners aim to leverage machine learning to deepen understanding of critical minerals, pushing for innovations that meet the growing demands of a resource-conscious world. With a precise focus on sustainable natural resource management, the dialogue within this project is dynamic, highlighting an intelligent, data-driven future where materials informatics plays a central role.

MAST3RBoost Project Details

The Horizon funded MAST3RBoost project brings together a consortium of thirteen partners from eight countries. MAST3RBoost stands for Maturing the Production Standards of Ultraporous Structures for High Density Hydrogen Storage Bank Operating on Swinging Temperatures and Low Compression. The project is geared towards developing novel ultraporous frameworks that will herald a disruptive path for hydrogen storage. By turning lab-scale synthesis protocols into industrial-like manufacturing processes, the team is working to secure a 30% increase of the working capacity of hydrogen to reach 10 wt.% and 44 g H2/l under conditions as low as 100 bar. Such advancements are expected to significantly impact hydrogen storage banks, providing a sustainable alternative to the current state-of-the-art technology that relies on compression at 700 bar.

Innovative Manufacturing and Sustainability Approaches

MAST3RBoost’s innovative strategy does not stop at breakthrough material properties; it extends into the realm of manufacturing and environmental sustainability. Lightweight vessels embedding these ultraporous materials are created with cutting-edge Wire-Arc Additive Manufacturing, designed to better fit on-board specific transportation spaces. There is also an active pursuit of recycled raw materials for the manufacturing process, drawing on waste agroforestry biomass and solid urban waste. Such eco-friendly practices, paired with Life Cycle thinking strategies, aim to minimize overall environmental impacts while advancing the field of hydrogen storage technology. The project exemplifies how high-tech innovation and sustainable practices can go hand in hand to address real-world challenges.

Project Impact on the SDGs

- SDG 7 – Affordable and Clean Energy: Striving for efficient hydrogen storage solutions.

- SDG 9 – Industry, Innovation, and Infrastructure: Advancing industrial-scale manufacturing processes.

- SDG 12 – Responsible Consumption and Production: Utilization of recycled raw materials and sustainable practices.

- SDG 13 – Climate Action: Contributing to Europe’s decarbonization and reduction of greenhouse gas emissions.

Bridging Academic Research with Industrial Innovation

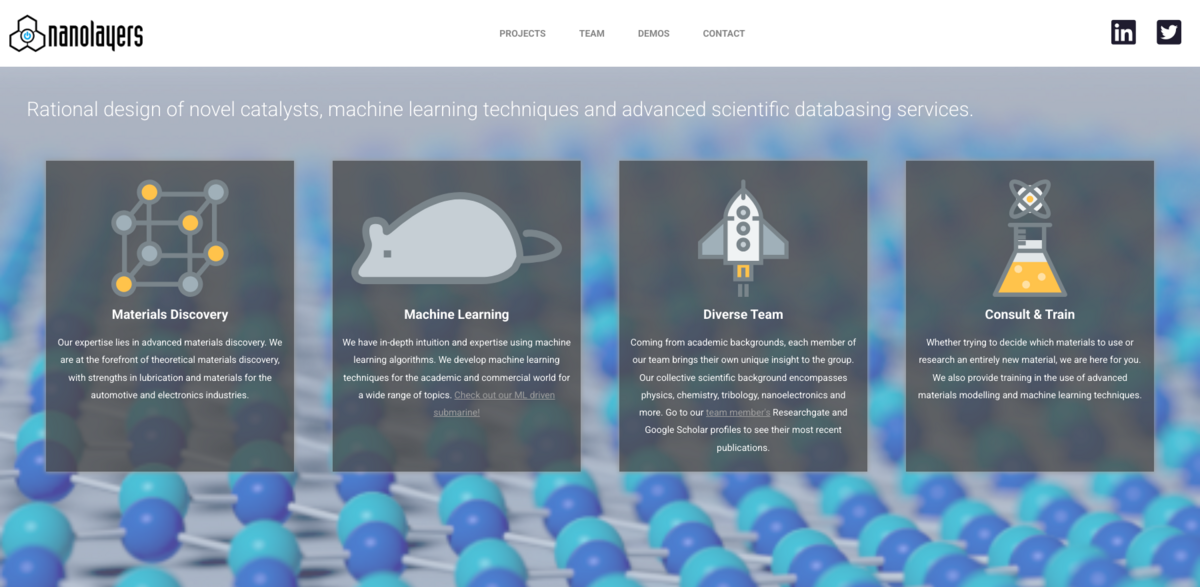

Nanolayers Research Computing plays a pivotal role in connecting academic breakthroughs with tangible, real-world applications. The projects encompass a diverse range of research, from quantum technologies to intelligent materials and advanced hydrogen storage solutions. Consistent with a forward-thinking philosophy, the partnerships and projects underscore a significant commitment to environmental sustainability, technological advancement, and resource efficiency. The seamless blending of academic insights with industrial demands is celebrated in these initiatives, carving a path for future innovations that truly make a difference. Through intricate collaborations and state-of-the-art manufacturing processes, the endeavors represent not just a technical achievement but a bold leap towards a cleaner, more efficient future…