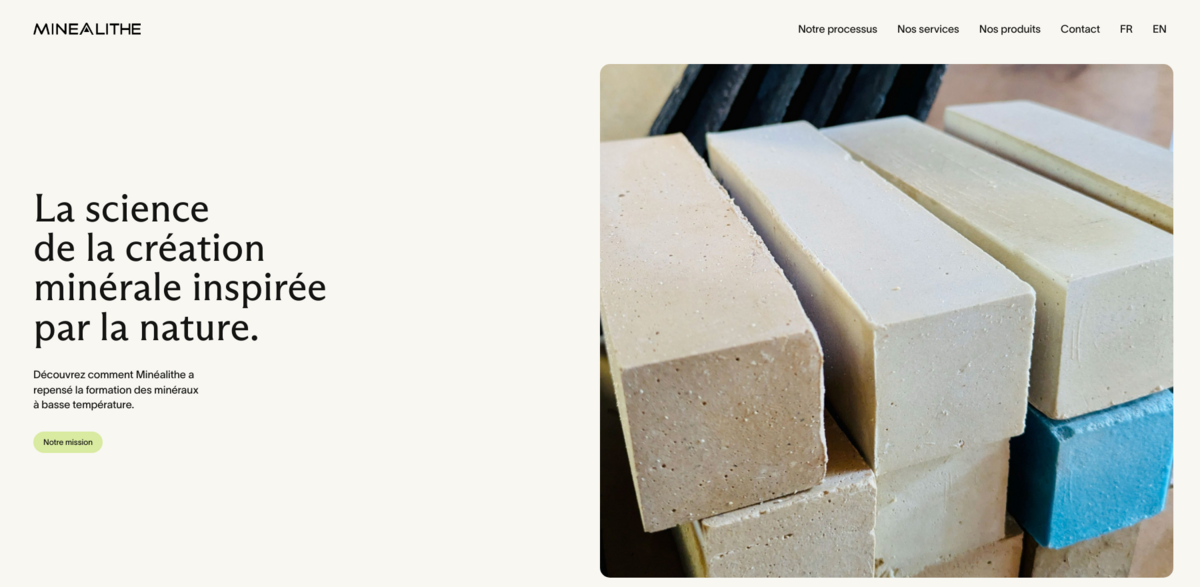

What is the Minéalithe Project?

Minéalithe is all about the science of mineral creation inspired by nature. Imagine rethinking how minerals form at low temperatures — that’s exactly what this project has achieved. Starting from a simple but fascinating fact: the human body can produce teeth or kidney stones at just 37°C in a watery environment. This sparked research back in 2005 to create minerals at low temperatures in liquid solutions. The goal? To mimic nature’s way of forming rocks but faster, without the heavy energy costs of traditional methods like calcination.

Main Benefits of Minéalithe’s Lithosynthesis©

The breakthrough here is called Lithosynthesis© — a patented chemical reaction that recreates stone and rock formation processes in an accelerated way. It’s not just another binder or cement; it’s a whole new science. Here are some key facts that make Minéalithe stand out:

- Technological Breakthrough: A totally new approach to mineral creation.

- Durability: Products last as long as natural rocks.

- Total Recycling: The materials are infinitely recyclable.

- 100% Ecological: Made from natural components, no petrochemicals or hydraulic binders.

- Energy Efficiency: Low temperature process, no heavy technology needed.

How Does the Process Work?

The Minéalithe process is pretty unique. It doesn’t rely on heavy machinery or high heat. Most of the work happens at room temperature or with just a bit of steaming. If the materials allow, ceramics can be fired at wood fire temperatures (around 850°C), producing products that can even withstand over 1500°C in refractory applications. And here’s the kicker — the components are all natural, sourced worldwide, and never calcined at high temperatures. It’s gentle chemistry at its best, using only natural reactions without any petrochemical additives.

Applications Across Industries

Lithosynthesis© isn’t just a one-trick pony. Its properties open doors to a variety of uses:

- Building: Molded, cast, extruded, printed, or coated materials.

- Recycling Industry: Encapsulating and inerting complex materials safely.

- Aeronautics and Automotive: Exploring innovative new applications.

- Medical: Conceptualizing 3D-printed bone prostheses.

- Decoration and Artisan Craft: Creating museum-quality elements and embellishments.

- Art and History: Adapting to all shapes and sizes for restoration or creation.

Recognition and Awards

Minéalithe’s work hasn’t gone unnoticed. It’s been showcased and awarded multiple times, including:

- Exhibition at Viva Technology, Paris 2019

- Grand Prize of the Golden Gesture, Paris 2020

- Exhibition at the Heritage Fair, Paris 2021

- Laureate of the European Metabuilding Competition, 2022

- Grand Prize for Re-Employment, BIM World Fair, Paris 2023

- World Forum on Buildings and Climate, Paris 2024

Environmental and Sustainable Development Goals Impact

- SDG 7: Affordable and Clean Energy — thanks to low energy consumption in production.

- SDG 9: Industry, Innovation, and Infrastructure — introducing groundbreaking mineral creation technology.

- SDG 11: Sustainable Cities and Communities — durable, recyclable building materials.

- SDG 12: Responsible Consumption and Production — total recycling and natural components.

- SDG 13: Climate Action — very low CO2 footprint and energy use.

- SDG 15: Life on Land — products return safely to nature without treatment.

The Future of Mineral Creation

Minéalithe’s discovery is a game-changer. By using a soft chemistry approach without cooking or high heat, it drastically reduces environmental impact. About 95% of the mineral components are used in their natural state, making the products reusable infinitely. And when their life cycle ends? They simply return to the earth, no treatment needed. It’s a deeply ecological process that could redefine how industries think about minerals, sustainability, and innovation. The future looks solid — literally.