What is GDI Energy Storage Technology?

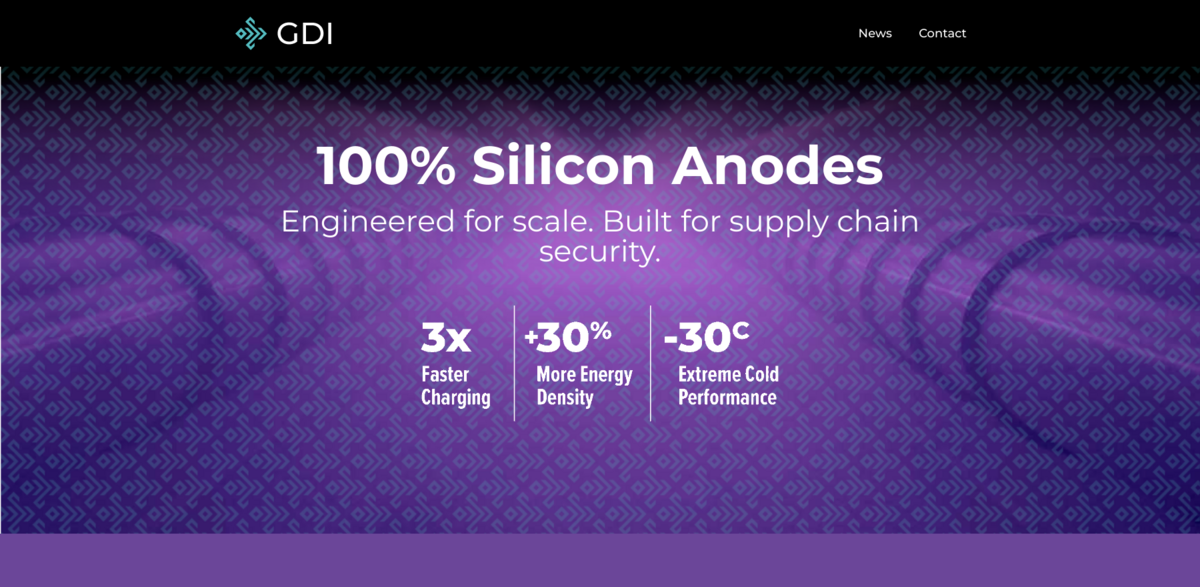

GDI Energy Storage Technology is shaking up the world of lithium-ion batteries with its groundbreaking 100% silicon anode technology. This innovation isn’t just a tweak—it’s a game changer. By replacing traditional materials with a pure silicon anode, GDI is pushing the limits of what li-ion batteries can do. Imagine batteries that charge faster, last longer, and pack more power—all thanks to this cutting-edge approach. It’s not just about better batteries; it’s about redefining energy storage for the future.

Main Benefits of GDI’s Silicon Anode Technology

Here’s what makes GDI’s technology stand out:

- 30% higher energy density than current cells—meaning more power in the same size battery.

- 80% of capacity achieved in just a 15-minute charge, translating to over 250 miles of EV range. Yep, that’s quick!

- Roll-to-roll manufacturing that rapidly scales using existing vapor deposition equipment—making mass production smoother and faster.

- Prevents overcharging and ends dendrite formation, thanks to a self-healing cell architecture that keeps batteries safer and more reliable.

- 100% silicon anode integrates directly into cell manufacturing—no milling, mixing, slurry coating, drying, or calendering needed. Plus, no more solvents involved.

How the Technology Works

At the heart of GDI’s innovation is the pure silicon anode. Unlike traditional graphite anodes, silicon offers a much higher capacity to store lithium ions. But silicon’s expansion during charging has been a big challenge—leading to cracking and short battery life. GDI’s self-healing cell architecture tackles this head-on, preventing dendrite formation and overcharging issues. This means batteries not only last longer but also stay safer throughout their life cycle.

Manufacturing Advantages

One of the coolest things about GDI’s technology is how it fits into existing manufacturing lines. The roll-to-roll process uses vapor deposition equipment that many factories already have. This means companies can scale up production quickly without investing in entirely new machinery. Plus, the elimination of milling, mixing, slurry coating, drying, and calendering steps simplifies the process and cuts down on environmental impact—no more solvents, which is a big win for sustainability.

Applications and Potential Uses

With its high energy density and rapid charging capabilities, GDI’s silicon anode batteries are perfect for electric vehicles, offering drivers longer ranges and shorter wait times. But that’s just the start. This technology could also revolutionize energy storage for renewable power, portable electronics, and even grid-scale solutions. Anywhere reliable, fast-charging, and high-capacity batteries are needed, GDI’s innovation could make a huge difference.

Impact on Sustainable Development Goals (SDGs)

- SDG 7: Affordable and Clean Energy – by enabling more efficient energy storage and faster charging.

- SDG 9: Industry, Innovation, and Infrastructure – through scalable manufacturing innovations.

- SDG 11: Sustainable Cities and Communities – by supporting cleaner transportation options with longer-range EVs.

- SDG 12: Responsible Consumption and Production – by reducing harmful solvents and simplifying manufacturing.

- SDG 13: Climate Action – by promoting cleaner energy storage solutions that reduce carbon footprints.

Looking Ahead: The Future of Energy Storage

GDI’s 100% silicon anode technology is more than just a breakthrough—it’s a glimpse into the future of batteries. Faster charging, higher capacity, and safer operation are no longer just goals; they’re becoming realities. As this technology scales, it could transform how energy is stored and used across industries, making electric vehicles more accessible and renewable energy more viable. The energy storage landscape is evolving, and GDI is right at the forefront, pushing boundaries and powering progress.