What Sandplast Injection Moulding Is All About

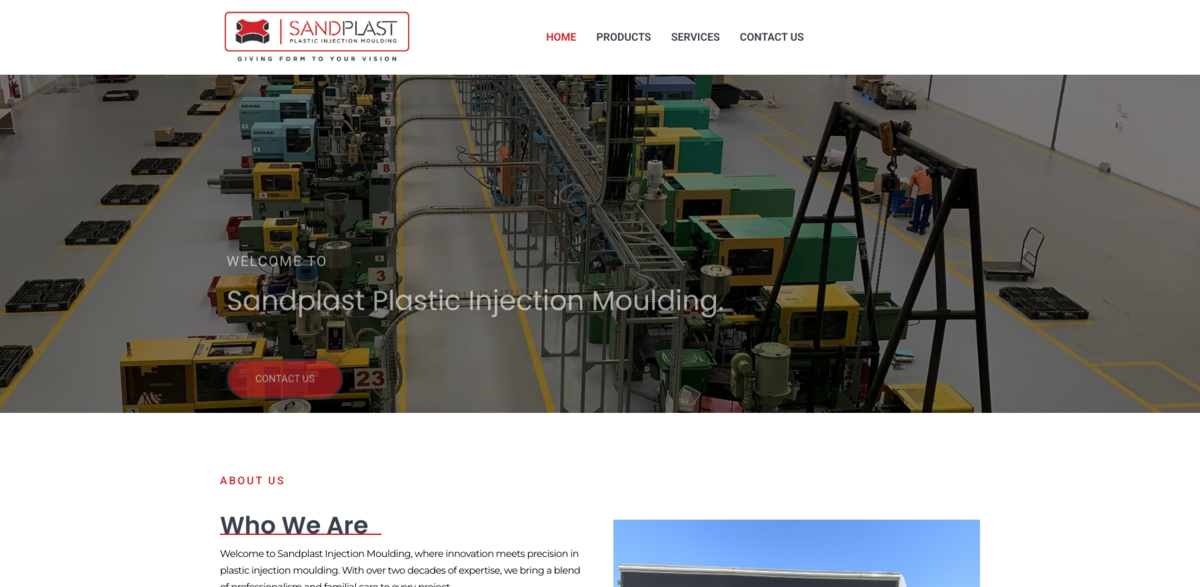

Sandplast Injection Moulding is where precision meets innovation in the world of plastic injection moulding. With over two decades of hands-on experience, this company combines professionalism with a touch of familial care, making every project feel personal. It’s not just about moulding plastics; it’s about shaping ideas into reality, with a team that’s passionate and dedicated to delivering exactly what clients need. From start to finish, Sandplast is right there, ensuring the process is smooth and the results, top-notch.

Main Benefits of Choosing Sandplast

Here’s a quick snapshot of what makes Sandplast stand out:

- 23 years of industry experience, blending skill with innovation

- ISO9001:2015 Quality Management System certified, ensuring consistent excellence

- FDA-approved manufacturing facility, meeting strict safety and quality standards

- A dedicated team of professionals who take pride in their craft and client satisfaction

- Flexible and committed approach, no project too big or too small

- One-stop injection moulding hub, offering customised and contract moulding services

Quality and Certification That Speak Volumes

Quality isn’t just a buzzword at Sandplast—it’s embedded in every step of the process. The ISO9001:2015 certification highlights a robust quality management system that keeps everything on track and up to standard. Plus, the FDA certification of their manufacturing facility adds an extra layer of trust, especially for clients needing compliance with stringent health and safety regulations. This dual certification combo means clients can rest easy knowing their products are made with care, precision, and accountability.

The Team Behind the Magic

Behind every successful project is a team that truly cares. Sandplast’s crew isn’t just skilled—they’re passionate about what they do. This dedication shines through in their willingness to accommodate client needs and tackle challenges head-on. It’s this blend of professionalism and personal touch that turns a simple injection moulding job into a tailored solution. The team’s flexibility means they’re ready to adapt, innovate, and deliver, no matter the project’s size or complexity.

Customisation and Flexibility at Its Best

One of Sandplast’s biggest strengths is its ability to offer customised products and services. Whether it’s a small batch or a large contract moulding order, the company’s approach remains the same: flexible, committed, and client-focused. This adaptability has made Sandplast a go-to injection moulding hub, providing everything under one roof. It’s not just about moulding plastic—it’s about moulding solutions that fit perfectly with what clients envision.

Project Impact and Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure – fostering innovation in manufacturing processes

- SDG 12: Responsible Consumption and Production – commitment to quality and efficient resource use

- SDG 8: Decent Work and Economic Growth – supporting skilled employment and professional development

- SDG 3: Good Health and Well-being – maintaining FDA standards for safe production environments

Why Sandplast Stands Out in the Injection Moulding Industry

At its core, Sandplast isn’t just about producing plastic parts—it’s about crafting success stories. The company understands that injection moulding is both a science and an art, requiring precision, creativity, and a deep understanding of client needs. With a proven track record, certified quality systems, and a team that’s genuinely invested in every project, Sandplast continues to set the bar high. It’s this unique blend of expertise, care, and innovation that keeps clients coming back and projects coming to life.