What Mechanical Performance Through Tolerance Analysis and Interface Design Is All About

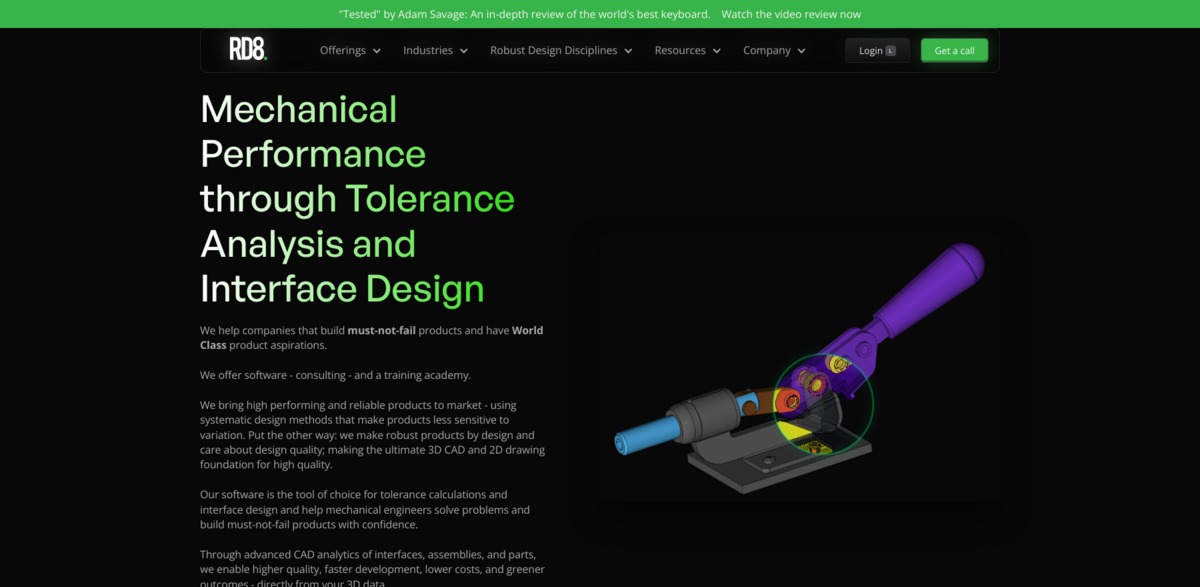

Mechanical performance through tolerance analysis and interface design is all about helping companies that build must-not-fail products and aim for world-class quality. It’s a systematic approach that makes products less sensitive to variation — basically, making them robust by design. This means focusing on design quality from the very start, using the ultimate 3D CAD and 2D drawing foundations to ensure high quality. The software and consulting services involved are the go-to tools for tolerance calculations and interface design, enabling mechanical engineers to solve problems confidently and bring reliable, high-performing products to market.

Main Benefits of Robust Design and Tolerance Analysis

Robust design isn’t just a buzzword — it delivers real, measurable benefits. Here’s what it brings to the table:

- Higher quality products that perform reliably under variation

- Faster development cycles, cutting down time to market

- Lower costs by eliminating over-specification and reducing manufacturing complexity

- Greener outcomes through efficient design and less waste

- Early identification of good designs, preventing costly iterations

- Clear understanding of which tolerances truly impact performance

- Better assembly behavior with fewer surprises downstream

Industries Where Robust Design Really Matters

Robust design shines brightest in industries where products are complex, volumes are large, and regulations are strict. Think aerospace, automotive, medical devices, and heavy machinery — places where failure is not an option. The more regulated and complex the product, the more value robust design delivers. It’s about setting the right design direction from day one and eliminating non-robust designs early on, so costly redesigns don’t slow things down.

Tolerances and Variation Management: The Heart of Robust Design

Not all dimensions are created equal — some matter a whole lot more than others. Managing variation starts with knowing exactly which tolerances affect performance. By mapping tolerance chains across assemblies, critical contributors to variation are identified and isolated. This means functional reliability is ensured where it counts, while over-specification is eliminated elsewhere. The result? Reduced costs, easier manufacturing, and a smoother path to market.

Constraints and Kinematics: Understanding Interfaces for Better Performance

Product performance is often defined by its interfaces — and that’s where most problems begin. Robust design kicks off by analyzing how parts place, move, and interact. By studying mechanical interfaces, constraints, and degrees of freedom early in the design process, overconstraints and misalignments can be uncovered before they cause headaches. This leads to more precision, cleaner movement, predictable assembly behavior, and fewer surprises down the line.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure — driving innovation in product design and manufacturing

- SDG 12: Responsible Consumption and Production — reducing waste through efficient design and manufacturing

- SDG 13: Climate Action — enabling greener outcomes by minimizing resource use and emissions

- SDG 8: Decent Work and Economic Growth — supporting industries with reliable, high-quality products that boost economic performance

How RD8 Supports the Robust Design Journey

RD8 offers a trifecta of support to make robust design accessible and effective. First, there’s the software — an engineering design tool that delivers robust design insights straight from your CAD data. Then, expert consulting provides engineering intelligence to tackle the toughest design challenges. And finally, the academy offers training to learn and master robust design methods. Together, these services empower engineers to build must-not-fail products with confidence and precision.