What is the GDI Project?

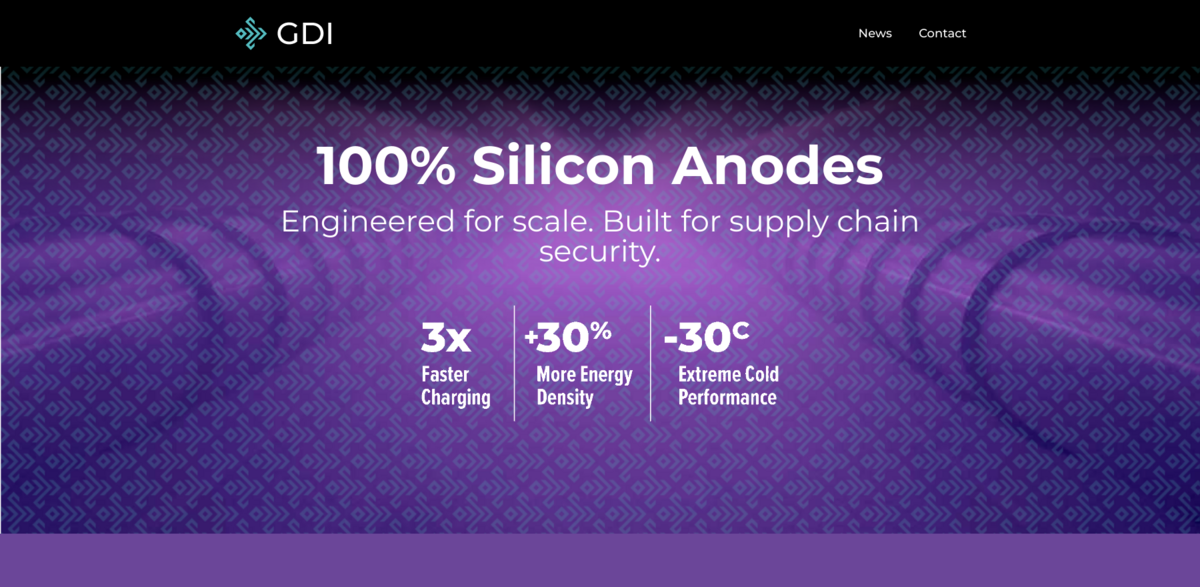

100% SILICON ANODES ENGINEERED FOR SCALE. BUILT FOR SUPPLY CHAIN SECURITY. GDI is a platform coating technology company that manufactures and sells both ultracapacitor and silicon li-ion electrodes, delivering breakthroughs in energy storage with patented silicon anode technology. GDI’s proprietary silicon anodes offer better performance over standard lithium-ion batteries by harnessing the power of silicon to achieve faster charging times, greater energy density, and exceptional safety. Located in Western New York, most of GDI’s team are former Kodak scientists and engineers with extensive knowledge of chemistry, advanced materials, scale-up, and roll-to-roll manufacturing. This cutting-edge approach ensures that every anode—whether it is the first or the millionth—maintains consistently high quality, meeting the rigorous demands of modern battery technology.

Main Benefit

GDI’s silicon anode technology delivers numerous key benefits that make it a game-changer in the energy storage arena. The main advantages include:

- 30% greater energy density compared with graphite.

- 3x faster charging speed, offering rapid turnaround times for power.

- Superior extreme cold performance, making it ideal for harsh operational environments.

- Enhanced security of supply, a crucial factor in today’s competitive battery market.

- Integration into high-production battery manufacturing processes for cost-efficient large-scale production.

Our Technology Simplified

GDI’s patented 100% silicon anodes use a continuous, flexible silicon layer that addresses swelling during charge and discharge cycles, effectively reducing the mechanical stress common in other silicon anode designs… The technology leverages AGC’s PlasmaMAX™ manufacturing process, which offers 5-10x faster silicon deposition. This breakthrough makes silicon anodes a commercial reality, ensuring that innovative concepts can move quickly from the lab bench to real-world applications. The approach is not only technically robust but also designed to be cost-efficient, harnessing existing fabrication equipment for seamless scalability.

Applications Across Industries

GDI’s silicon anode technology is versatile and integrates seamlessly into existing high-production battery manufacturing systems, powering the products of tomorrow. Whether the end application is drones for defense or civil use, military wearable technologies, cutting-edge medical devices, electric vehicles, or electrified aerospace products, this technology is engineered to meet specific performance needs. The ability to transition rapidly from development to mass production represents a major breakthrough, where faster charging, greater energy density, lighter weight, and solid supply security translate into tangible benefits for a wide range of industries. It is this adaptability that puts GDI at the forefront of battery innovation.

Growth and Recognition

Over the past few years, GDI has not only pushed the boundaries of silicon anode technology but has also received significant recognition on the international stage. Recent media headlines showcase GDI’s achievements: an $11.5M follow-on funding round led by Helios Climate Ventures, Impact NY, and InnoEnergy; a pioneering pilot production in Europe; and discussions with CEO Robert Anstey about commercialization plans set for 2026. Adding to this momentum, the company secured a €20 million quasi-equity loan from the European Investment Bank to further develop its 100% silicon anode technology. The U.S. Army xTech competition prize and accolades from the EIT InnoEnergy 2022 TBB pitching competition validate the technology’s promise, proving that GDI’s innovations are both groundbreaking and commercially viable. These recognitions have helped open new doors and solidify GDI’s role as one of the most promising startups in the energy sector.

Continued Innovation and Collaboration

GDI’s journey is defined by its passion for innovation and its commitment to collaboration with product and battery manufacturers across various industries. The company’s mission is to enable fast charging energy storage technologies that will further the utilization of renewable energy, mass transportation, and electric mobility. GDI systematically collaborates with partners ranging from military technology developers to medical equipment manufacturers to ensure that its silicon anodes can be adapted to any lithium battery architecture. This collaborative spirit ensures that every design, whether targeting commercial or specialized military applications, receives the benefit of GDI’s advanced technology and proven, cost-efficient production methods… it’s all about creating solutions that meet diverse and demanding performance criteria.

Project Impact

- SDG 7: Affordable and Clean Energy – by innovating in fast charging and energy-dense storage solutions.

- SDG 9: Industry, Innovation and Infrastructure – through advanced manufacturing processes and scalable technology.

- SDG 11: Sustainable Cities and Communities – by powering sustainable transport and urban mobility innovations.

- SDG 13: Climate Action – by enhancing renewable energy utilization and reducing dependencies on traditional energy storage materials.

The Road Ahead

GDI’s mission remains clear – to design and produce the highest power density electrodes per dollar for the ultracapacitor market and the highest energy density per dollar silicon anode for the Li-ion market. The strategy is simple: create products that can be manufactured at massive scale while keeping production economics attractive. This approach is not only directed at fortifying supply chains but also at ensuring that cutting-edge energy storage solutions are accessible and reliable for industries around the globe. With pilot production already underway in Europe and exciting applications in the military sector poised for launch, GDI is on track to redefine the future of battery technology. The journey continues with consistent innovation, strong partnerships, and a relentless drive to power the products of tomorrow… a future where advanced design meets real-world demand.