What is SKIPPER NDT?

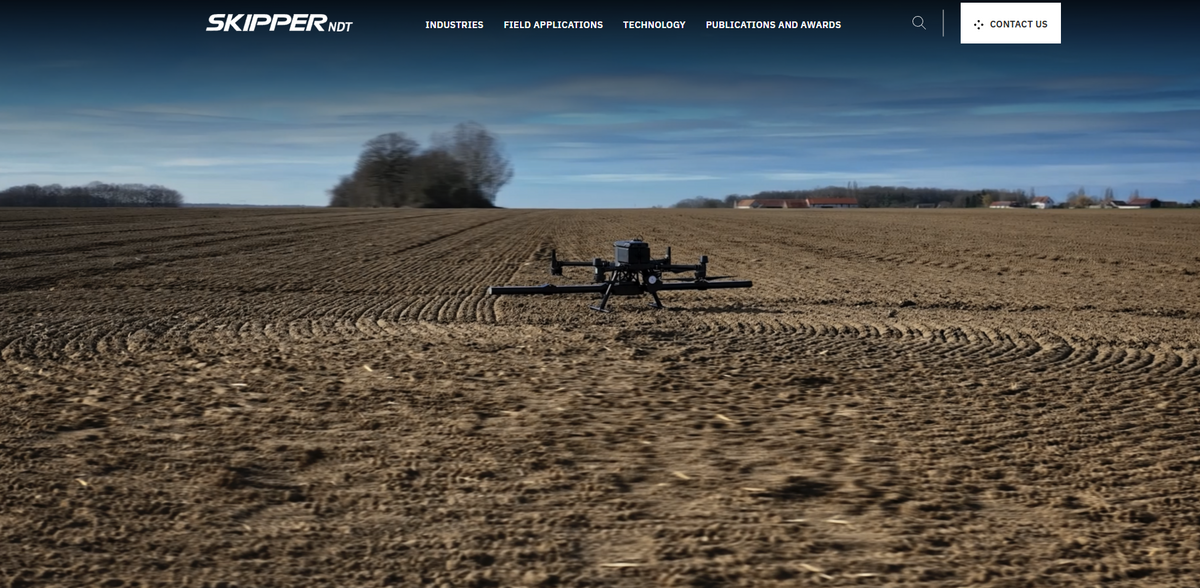

SKIPPER NDT: PIPELINE MAINTENANCE AUTOMATION TECHNOLOGY – a name that stands for precision and efficiency. Buried pipelines have long been recognized as the most secure and efficient means to transport vital resources such as water and energy sources. In a world where safety and efficiency go hand in hand, ensuring precise geospatial positioning of these underground infrastructures becomes absolutely essential for protecting people and the environment. Using contactless magnetic technology for the inspection of buried oil & gas pipelines, this project emphasizes the safety of people, the environment, and assets. It is all about guarding against third-party damage while accurately identifying pipeline movement on unstable slopes… truly a revolutionary approach to pipeline maintenance.

Main Benefits

The benefits of SKIPPER NDT are numerous and robust. The approach offers unmatched precision along with cost-efficiency, making it a preferred choice in various challenging scenarios. A few key figures and facts include:

- Industries: Water Utilities, Energy, Electricity, Hydrogen

- Field Applications: Water Crossing, Bending Strain Analysis (BSA), DOC Assessment, Decommissioned Sites and Abandoned Wells

- Products: Argos (Hardware), Atlas (Hardware), Admiral (Software), Orion (Software), Morpho (Software)

- Technology: Contactless magnetic inspection providing advanced safety features

- Functionality: Precise geospatial positioning to ensure optimal pipeline operation

Innovation Through Automation

Innovation drives every facet of this project. Leading-edge technology and cutting-edge functionalities come together to anticipate tomorrow’s challenges and ensure the longevity of infrastructures. The system integrates automation seamlessly into field operations, enhancing the overall efficiency while offering a level of accuracy that sets it apart from traditional maintenance methods. This blend of hardware and software solutions tackles complex pipeline issues head-on… proving that bridging technology with real-world applications is a winning formula.

Inspection Technology in Action

At its core, SKIPPER NDT is all about precision and reliability. The use of contactless magnetic technology enables the inspection process to be as non-invasive as possible, meaning that the integrity of the pipeline remains uncompromised during evaluations. By focusing on both cost-efficiency and accuracy, this approach ensures that pipeline maintenance is performed with the highest quality standards. It is a method that not only reduces downtime but also boosts confidence in the safety and performance of critical infrastructures.

Operational Sectors and Field Applications

The project operates across a diverse range of industries, which include crucial sectors like water utilities, energy, electricity, and hydrogen. This diversity enhances the overall impact, showing that precision technology is not just limited to one field but is rather applicable on multiple fronts. Field applications are varied and incredibly targeted: water crossing, bending strain analysis (BSA), DOC assessment, and even tasks at decommissioned sites and abandoned wells. With innovative products such as Argos and Atlas in hardware, and Admiral, Orion, and Morpho in software, each component plays a vital role in delivering a full spectrum of practical, automated solutions. This comprehensive approach paves the way for reliable operation even in the most challenging environments… making it a versatile choice for modern pipeline maintenance needs.

Safety and Sustainability in Infrastructure

Safety and sustainability are at the forefront of every initiative related to SKIPPER NDT. Precise positioning and automated measures contribute significantly to the overall protective framework for critical infrastructures. In a dynamic environment where third-party damage and structural movement are real threats, this solution reduces risks while bolstering the resilience of buried pipelines. The system’s capacity for anticipating and mitigating potential issues not only shields people and the environment but also supports long-term infrastructure stability. Efficiency in design leads to dependable operations—this is technology designed to work in tandem with nature and modern engineering.

Project Impact

- Goal 6: Clean Water and Sanitation – Ensuring safe water supply by protecting the primary infrastructures.

- Goal 7: Affordable and Clean Energy – Supporting sustainable energy transport through secure pipelines.

- Goal 9: Industry, Innovation, and Infrastructure – Driving innovation that underpins robust and modern infrastructure.

- Goal 11: Sustainable Cities and Communities – Contributing to communities with secure and efficient resource transport.

- Goal 13: Climate Action – Helping reduce environmental risks through technologically advanced pipeline maintenance.

Future Outlook

Innovation through automation not only addresses present challenges but also sets the stage for future growth in the industry. Latest news and scientific publications continue to share inspiring stories, practical tips, and advice about these solutions and their wide-ranging uses. As research and development work hand-in-hand with practical field applications, there is a constant flow of fresh insights that drive further improvements in pipeline safety. The integration of hardware and software systems, such as Argos, Atlas, Admiral, Orion, and Morpho, demonstrates that a blend of traditional engineering and emerging technology is powerful indeed. The dynamic advancements in automation ensure that maintenance strategies will keep evolving to meet rigorous safety standards. With each breakthrough, there comes a promise of enhanced precision and reliability, ensuring that the longevity of vital infrastructures remains secured for generations to come… a future where every twist and turn in a buried pipeline is monitored with meticulous care.