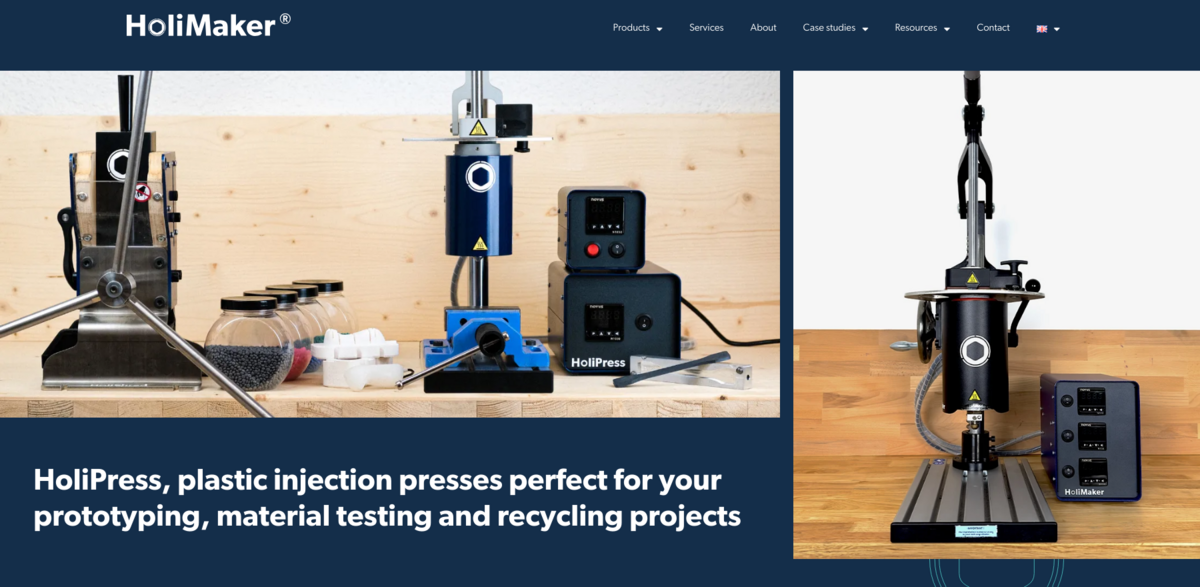

What is the HoliMaker Project?

HoliMaker designs, manufactures, and assembles in France the HoliPress plastic injection presses, a micro-industrial device for manually injecting plastics. This innovative project facilitates prototyping, education in plastics, material testing, recycling of plastic waste, and even the production of pre-series parts. By combining traditional quality with modern flexibility, HoliPress empowers professionals to move from idea to injection with ease – think about producing finished parts every 3 or 5 minutes, depending on the model. With its intuitive design and French-manufactured craftsmanship, this project bridges the gap between conventional injection molding and the flexibility of 3D printing.

Main Benefit and Key Figures

The standout benefit of HoliPress is its ability to quickly transform design ideas into functional plastic parts, while lowering both the time and cost associated with traditional methods. The machine is engineered to accommodate a wide range of plastic materials, whether they are virgin, recycled, or bio-based. Key figures and facts include:

- HoliPress 16: 160mm (L) x 540mm (W) x 410mm (H), weight 11 kg (excluding accessories), injection volume of 16 cm³, and a production rate of 1 part every 3 minutes.

- HoliPress 38: 240mm (L) x 410mm (W) x 715mm (H), weight 35 kg (excluding accessories), injection volume of 38 cm³, and a production rate of 1 part every 5 minutes.

- Injected parts achieve industrial quality – they are 20 times faster than FDM 3D printing with a finish and mechanical strength comparable to traditional injection molding.

Innovative Design and Flexibility

HoliPress offers great design freedom by eliminating many of the constraints associated with traditional industrial standards. With its hybrid, robust, and multi-material design, it opens up a world of possibilities. The manual nature and lever rotation material feeding system make switching between different plastics a snap – no more hassles of changing machines for different materials. The ease of loading and intuitive controls allow for rapid transitions, while the compatibility with various injection materials (up to 320°C) makes it a versatile tool in any prototyping ecosystem. It’s all about speed, convenience, and creative freedom… an inviting option for the dynamic world of plastics processing.

Industrial Quality and Safety

Industrial quality is at the heart of HoliPress. The equipment has been designed to approach the finish and mechanical strength of industrial plastic injection through rigorous testing, including equivalent tensile testing. Despite the manual force required to operate it, each finished part emerges efficiently, showcasing reliability and durability. Moreover, the machine is built with a robust, characterized, and insulated design that prioritizes safety. A personal protective equipment (PPE) kit including safety glasses and thermal gloves is provided, ensuring that maintenance and operation are conducted with maximum safety. This focus on safety and quality echoes the careful craftsmanship within the HoliMaker project.

Versatility Across Industries

The HoliPress is not limited to a single application but adapts seamlessly to various sectors, ranging from mechanical parts for automobiles to components in electronics and even toys. Its adaptability is evident in every facet – from creating molds through diverse processes such as machining (using steel, aluminum, copper, or dense wood), 3D printing (resin or FDM), to laser cutting and engraving of PMMA, metals, or dense wood. This broad industry applicability makes HoliPress a pivotal tool, especially in engineering and product design, health and pharmaceutical sectors, communication objects, and education or training environments. It truly symbolizes the future of accessible and innovative injection molding.

Efficiency in Prototyping and Production

The beauty of the HoliPress lies in its ability to shorten the time from design to production dramatically. Makers and designers can now prototype plastic parts without relying on intermediaries or extended wait times associated with metal mold production. Internally printed 3D molds provide a cost-effective way to test and verify each production step before launching a wider series production. This seamless integration in the prototyping ecosystem not only saves time but also reduces costs significantly. The flexibility provided by the machine transforms the traditional production line into an agile, experimental space where creativity is matched with precision and speed.

Project Impact: Advancing Sustainable Development Goals

- SDG 9: Industry, Innovation, and Infrastructure – Innovating in plastic injection and manufacturing processes.

- SDG 12: Responsible Consumption and Production – Incorporation of recycled and bio-based plastics emphasizes waste reduction and environmental care.

- SDG 4: Quality Education – Providing tools and workshops for plastics processing and circular economy awareness.

- SDG 13: Climate Action – Promoting eco-designed production methods as part of the circular economy initiatives.

Empowering the Future of Plastic Processing

HoliMaker, with its HoliPress machines, stands as a beacon of innovation and sustainability in the plastics industry. As it continues to develop training and awareness workshops on plastics processing and the circular economy, the project not only enhances industrial capabilities but also fosters a culture of responsible production. With precise engineering, user-friendly operation, and a robust safety framework, HoliPress empowers professionals and enthusiasts alike to explore the next frontier of plastic manufacturing. It is a prime example of how technology, when combined with smart design and environmental insight, can revolutionize traditional processes and help shape a more responsive and sustainable future for various industries.