What the Project Is: Advanced Optical Sensor Solutions

TecSense GmbH is an innovative producer of optical oxygen and CO2 sensors for applications in food and industrial process control as well as scientific research. Located at Teslastraße 4 in Grambach, Austria, the company specializes in developing and producing optical sensors that are incredibly versatile and reliable. These sensors are designed to enable online control in various production processes – ensuring quality in food packaging, pharmaceutical formulations, chemical manufacturing, and biotechnology research. With products such as TecPen Dot, TecPen Fiber, TecPen Fluid, TecPen MAP, Tec Micro, TecPen Weld, Ox100, and HSA, the project represents a leap forward for industries sensitive to gas measurements. The optical sensors allow for precise control over oxygen and CO2 levels, which, in turn, guarantee the reliability of research and development outcomes. The result is an inspiring blend of scientific precision and practical utility – a solution that meets the high standards of modern industrial processes… offering immediate readiness without any warm-up time, a compact design, and high measurement accuracy.

Main Benefit: Key Figures and Facts

Some of the defining features and benefits include:

- TecPen Weld: An optochemical O2 sensor system designed for gaseous media; it monitors oxygen concentration in forming gases to ensure the highest quality welds while preventing oxidation.

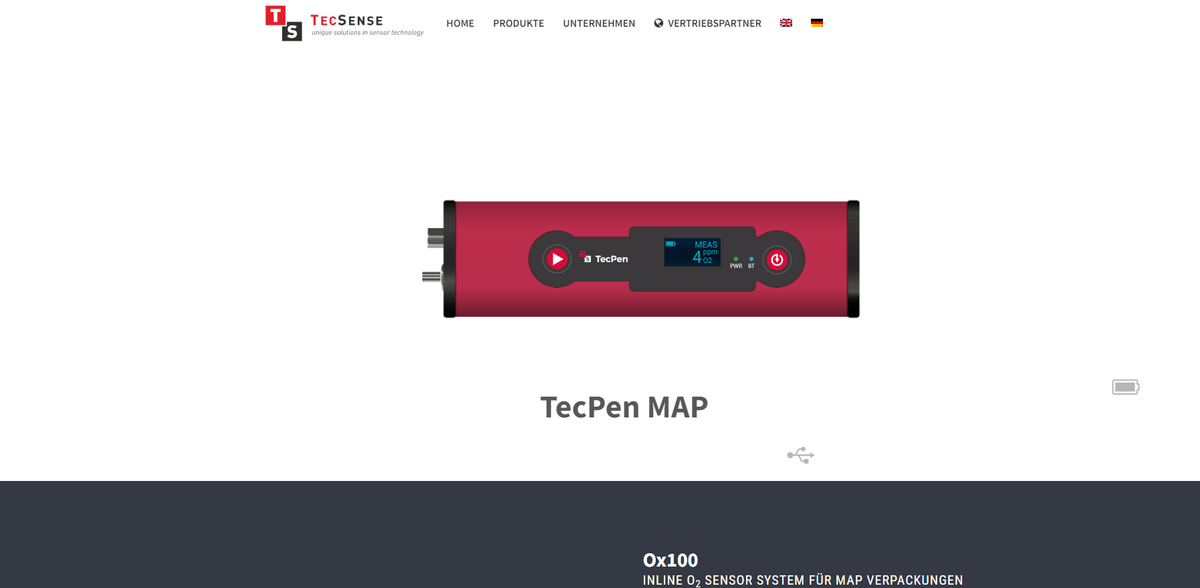

- TecPen MAP: Guarantees quality assurance and production control with high flexibility, immediate readiness, and a fully automatic zero-point adjustment at each start – even suitable for very small gas volumes.

- TecPen Fluid: Focused on quality control in beverages, featuring integrated memory and USB-enabled data transfer to streamline operations.

- TecSense HSA: Offers rapid determination of headspace volume within 30 seconds alongside analysis of O2, foreign gas, and CO2 content, including calculation of oxygen concentration (mg/L) in bottles.

- Common benefits include immediate readiness for use, compact design for high flexibility, and exceptional measurement accuracy across all products.

Product Highlights: Detailed Sensor Features

Each product in the TecSense range comes with its unique set of characteristics. Take, for example, the TecPen Weld system – this optochemical sensor allows for real-time monitoring of oxygen in a forming gas environment, ensuring that weld quality is not compromised by oxidation. Similarly, the TecPen MAP system is tailored for quality assurance and production, boasting a design that handles even the minutest gas volumes with flawless precision. Meanwhile, TecPen Fluid provides top-notch control in the beverage industry, integrating a memory system and USB data transfer, which simplifies the recording process. There is also the TecSense HSA module that quickly determines headspace volume and vital gas concentrations, turning what once might have been a lengthy process into a rapid and efficient one… all these features work together to underline the commitment to precision and reliability.

Technological Excellence Across Solutions

The technologies behind these products combine the best in optical sensor design with an understanding of industrial needs. With no warm-up times required, these instruments are ready for immediate use, offering a dynamic response when monitoring crucial parameters in production lines and research laboratories. The compact designs ensure that even limited space environments can benefit from high-quality sensor integration. Not only do these sensors aid in achieving consistent production standards, but they also contribute to enhanced research and development outcomes by providing stable, reliable data. The ease of integration and operation helps production lines run smoothly, which is paramount in industries where every minute counts – this blend of simplicity and sophistication truly sets these solutions apart.

Quality Assurance and Innovation in Process Control

Quality control in modern industrial settings demands both precise measurement and robust data handling. TecSense’s optical sensors bring together these qualities by ensuring that every measurement, whether in food packaging or pharmaceutical production, meets stringent quality standards. It is an approach that not only safeguards product integrity but also pushes the boundaries of what is possible in sensor technology. With additional features such as in-built data transfer via USB, these solutions are designed to integrate seamlessly into existing quality control systems. The immediate readiness and high measurement accuracy mean that downtime is minimized, and operational efficiency is maximized. In short, these sensors serve as the silent drivers behind consistent quality assurance in multiple sectors.

Expanding Applications Across Industries

The applications of these optical sensors extend well beyond the laboratory or manufacturing floor. They are instrumental in monitoring oxygen concentrations for weld processes, ensuring that structural integrity is maintained under varied conditions in industrial settings. When used in the food packaging process, these sensors help in maintaining the freshness and safety of food products by providing real-time oxygen and CO2 readings, thereby directly impacting product shelf life and consumer safety. Similarly, in the realm of beverages, the rapid determination of headspace volume and gas content ensures that quality is never compromised. These diverse applications illustrate how technological excellence meets real-world needs – a true testament to innovative sensor design in today’s high-paced industrial environment.

Project Impact: SDG Alignment

- SDG 9: Industry, Innovation, and Infrastructure – through the development of cutting-edge sensor technologies.

- SDG 12: Responsible Consumption and Production – by ensuring quality control practices that minimize waste and maximize efficiency.

- SDG 3: Good Health and Well-being – improving food safety and pharmaceutical standards by enabling precise measurements.

- SDG 2: Zero Hunger – by bolstering food packaging processes and ensuring the integrity of food products.

- SDG 17: Partnerships for the Goals – fostering collaboration across various industries to drive technological innovation.

Looking Forward: The Future of Optical Sensing

The journey of optical sensors in industrial and scientific applications is well underway, and the evolution shows no signs of slowing down. Enhanced sensor technology, as demonstrated by the TecSense portfolio, paves the way for more streamlined and integrated production environments. As industries continue to adopt advanced methods for quality assurance, the integration of such reliable sensor systems will become increasingly important. These products, with their immediate readiness and precision, represent a critical step towards ensuring that industry and research can meet ever more demanding standards. With a focus on innovation and efficiency, the future of optical sensing looks promising, offering reliable process control and the means to capture key data in real time… truly a revolution in sensor technology.