What the Project Is

A FASTER, MORE RELIABLE BUILDING SOLUTION is now a reality in the construction industry. Plant Prefab helps general contractors, architects, and developers deliver housing 20-50% faster than traditional site-based methods. Offering built-to-spec panelized and modular components, this project saves time, controls costs, and reduces risk on multi-unit developments. Leveraging cutting-edge virtual design and construction (VDC) alongside automated manufacturing, the approach uses a combination of panelized, modular, and hybrid systems that precisely meet each project’s design, site, and budget requirements. In short, this is a next-generation solution for residential construction that delivers speed, quality, and sustainability all in one.

Main Benefit

The key benefits of this innovative construction project shine in every phase of development. The process provides efficiency, quality, and robustness to the building process – made possible by a purpose-built 270,000-square-foot factory in Tejon Ranch, California that employs proven German manufacturing equipment, enhanced by the innovative Plant Virtual Build™ digital modeling process. Below are some key figures and facts:

- Saves time: 20-50% faster housing delivery compared to traditional methods

- Cost Control: Efficient budgeting through precise design and automated manufacturing

- Risk Reduction: Advanced digital modeling minimizes on-site uncertainties

- High Quality: Factory-driven production ensures unmatched production standards

- Sustainability: Utilizes green manufacturing processes for durable, eco-friendly construction

Seamless Production and Virtual Design & Construction Integration

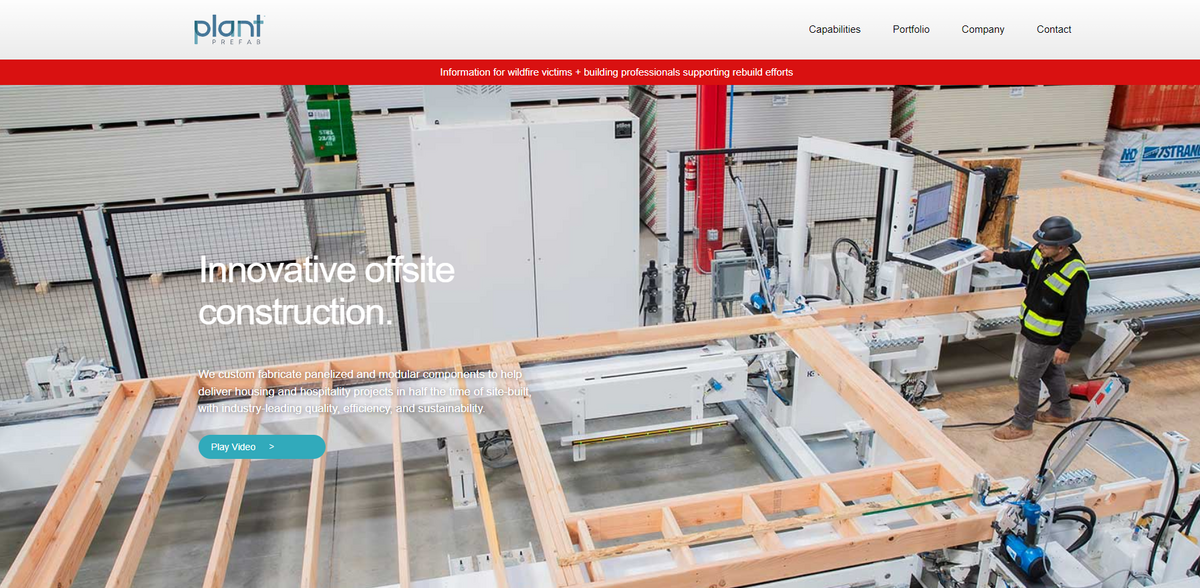

At the core of the project is a state-of-the-art factory that marries innovative production with precision digital modeling. With a dedicated team of in-house skilled laborers and CAD engineers, this project creates a complete 3D model of every structure—coordinating all structural, mechanical, electrical, plumbing, and sprinkler systems. What takes shape is a digital blueprint that produces factory shop drawings, optimal bundling for truck load diagrams, and detailed installation manuals. The digital, virtual design and construction (VDC) approach not only supports speed but also ensures accuracy that removes guesswork from manufacturing and logistics. It’s a process that truly speaks to the benefits of technology in construction… and one that has already made a significant impact for projects ranging from multifamily built-to-rent and townhomes to affordable housing and student residences.

Tailored Panelized & Modular Solutions

Flexibility is at the heart of the system. The project offers a panel-based building system that provides full structural building envelopes in record time—delivering dry-in results in just half the time of conventional site-built methods. Detailed components include floor panels, exterior and interior wall panels, roof panels, windows, decks, balconies, pergolas, stairs, and structural steel. In addition, volumetric modules can be coupled with panelized components for those projects that demand even faster speed to market. The modular finish is designed per specification and includes sprinklers, cabinetry, appliances, HVAC equipment, interior millwork, light fixtures, plumbing fixtures, as well as AV, security, and smart home features. The customization options allow the solution to be adapted to a wide range of residential project types—whether it’s single-family communities or workforce housing.

Innovative Preconstruction & On-Site Logistics

A seamless starting point is critical, and the project begins with an experienced design and preconstruction phase. For projects up to four units, an award-winning design studio leads the creative process, ensuring that all elements are in perfect alignment with the construction strategy. Larger projects benefit from design-assist collaborations with the architect of record to optimize production efficiency in the factory. The preconstruction team provides thorough plan reviews and pricing, value engineering, and professional supply chain management along with site logistics planning and coordination. Every step, from the initial assessments to final on-site installation, is meticulously planned to guarantee that transportation and logistics are handled in the most efficient manner possible.

Efficient and Sustainable Production

A blend of automated manufacturing and human expertise creates an end-to-end system of efficiency. All panelized and modular components are manufactured in a controlled, purpose-built facility with state-of-the-art machinery that custom produces components with industry-leading speed and quality. To ensure the highest standards, every component is inspected by a third-party, state-certified agency before it is labelled for on-site installation. Sustainability is a major focus; the production methods are designed to achieve remarkable sustainability outcomes, reducing waste and ensuring that each building is both robust and environmentally friendly. This ensures that even as construction speeds increase, the quality and longevity of the buildings remain uncompromised.

Project Impact on Sustainable Development Goals

- Industry, Innovation and Infrastructure (SDG 9) – Boosting advanced manufacturing and digital innovation in construction

- Sustainable Cities and Communities (SDG 11) – Supporting resilient infrastructure and sustainable housing solutions

- Responsible Consumption and Production (SDG 12) – Promoting eco-friendly manufacturing practices and reduced waste

- Climate Action (SDG 13) – Incorporating energy-efficient processes and sustainable production methods

Future of Efficient Residential Construction

The forward-thinking approach embodied by this project sets a new standard in residential construction. Emphasizing precision, speed, and sustainability, the innovative building solution evolves alongside modern construction demands. General contractors, architects, and developers looking for an edge in today’s competitive market will appreciate the project’s unmatched quality and reliability. The integrated services—from end-to-end preconstruction support to tailored modular and panelized solutions—form a cohesive process that transforms the way housing is built. With digital modeling that drives efficiency at every level and a clear commitment to sustainability, this project is more than an alternative to site-based methods; it is a transformative leap into the future. By harnessing the latest in VDC and automated manufacturing, the projects not only meet contemporary design standards but also pave the way for a construction industry that values speed, flexibility, and environmental responsibility… all while continuing to set new benchmarks in residential construction.