What is the Litech Sensor System?

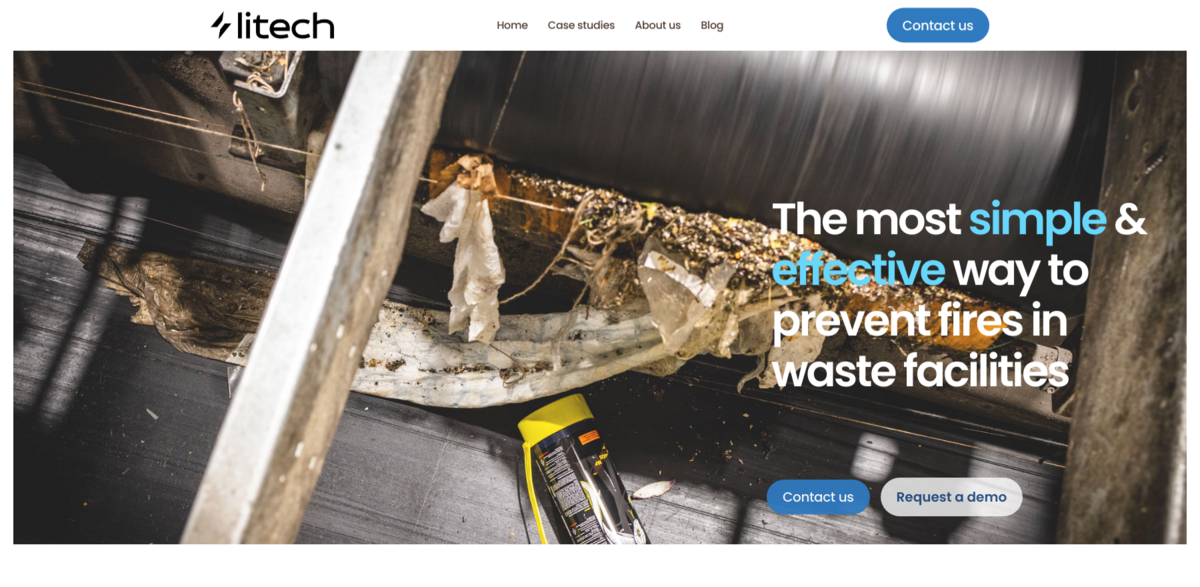

Imagine a gas bottle detected right on the conveyor belt during the waste sorting process. That’s exactly what Litech’s sensor system does — it’s the simplest and most effective way to prevent fires in waste facilities. This compact sensor fits seamlessly into any recycling plant, making fire prevention smarter and easier than ever before. It’s not just tech talk; this system won the Climate Tech Startup of the Year 2024 award, proving its impact and innovation in the field.

Main Benefits of the Litech Sensor System

Every year, hundreds of costly fires and explosions happen at waste facilities. Most of these disasters are caused by misclassified lithium batteries and nitrous oxide canisters. Litech’s sensor system tackles this problem head-on. Here’s what makes it stand out:

- Simple modular design: Plug-and-play hardware that fits where other systems can’t.

- Easy installation: Installs directly on existing sorting lines without disrupting operations.

- Scalable: Add more sensors as needed to cover larger areas or more lines.

- MIS-based detection: Uses multiple light spectra for earlier and more accurate threat detection compared to basic RGB cameras or heat sensors.

- Real-time actionable data: Monitor risk zones, track hazardous item frequency, and get insights to improve uptime and performance.

- Proven success: Pilot with Oslo Municipality and Litech showed improved operational reliability and fire risk management.

How Does the Litech System Detect Threats?

Unlike traditional sensors, Litech’s system uses MIS technology — that’s multispectral imaging — which reads multiple light spectra. This means it can spot threats like gas canisters, batteries, and metals much earlier and with greater accuracy. Basic RGB cameras or heat sensors just don’t cut it when it comes to identifying these hidden dangers on a busy conveyor belt. This advanced detection helps facilities act before a fire or explosion can even start.

Is the Litech System Ready for Commercial Use?

Absolutely. The system has been tested in real-world conditions during a pilot project with Oslo Municipality and Litech. The feedback? It’s easy to integrate, doesn’t disrupt daily operations, and significantly improves both safety and operational reliability. So yes, it’s not just a concept — it’s ready to be deployed in commercial recycling plants right now.

Installation Requirements and Flexibility

One of the best things about Litech’s sensor system is how straightforward it is to install. Thanks to its modular, plug-and-play design, it fits directly onto existing sorting lines without the need for major overhauls or downtime. Facilities can scale the system up or down depending on their needs, making it a flexible solution that adapts to different plant sizes and layouts. No fuss, no hassle — just effective fire prevention.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure — promoting resilient infrastructure and sustainable industrialization through advanced sensor technology.

- SDG 11: Sustainable Cities and Communities — enhancing safety in waste management facilities, contributing to safer urban environments.

- SDG 12: Responsible Consumption and Production — improving waste sorting accuracy and reducing hazardous incidents.

- SDG 13: Climate Action — preventing fires that release harmful emissions, supporting climate change mitigation efforts.

- SDG 3: Good Health and Well-being — protecting workers and communities from fire-related injuries and hazards.

Can Facilities Test the Litech System Before Committing?

Yes, testing the system before making a full commitment is possible. This approach allows facilities to see firsthand how the sensor integrates with their existing lines and how it improves safety and operational control. It’s a smart way to ensure the technology fits the unique needs of each plant — no surprises, just peace of mind.