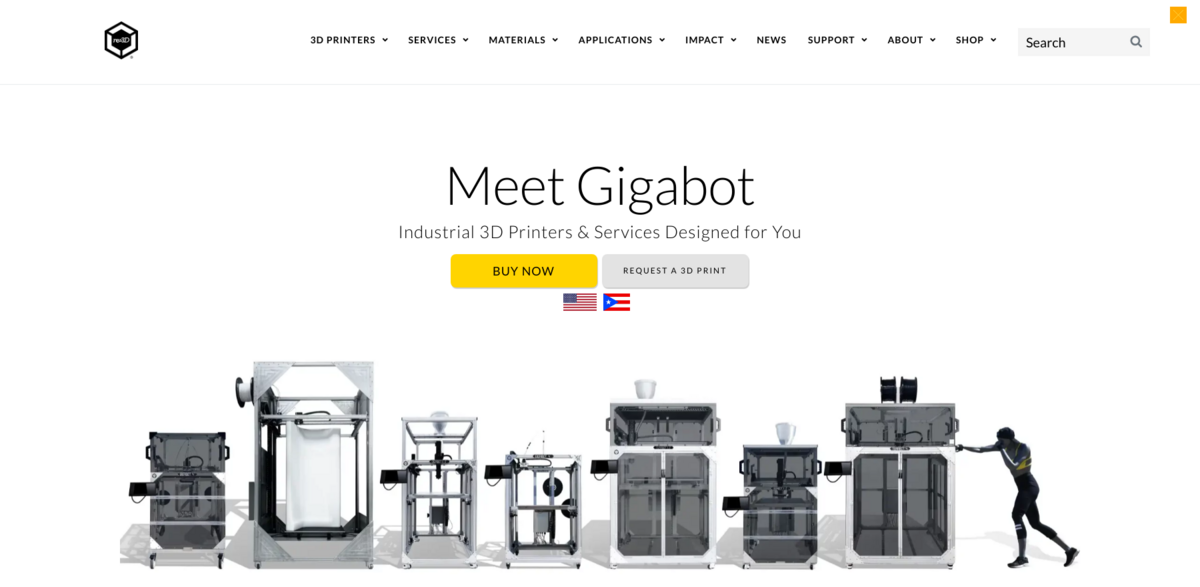

What is Gigabot?

Gigabot is an industrial 3D printing solution designed to break down the barriers of cost and scale in the world of large-scale manufacturing. It’s not just any 3D printer—it’s affordable, high-quality, and built for industrial use, crafted with precision in Texas by the re:3D team. Whether you’re printing with pellets, flake, or filament, Gigabot is engineered to meet your 3D printing needs with versatility and power. From human-scale objects to complex parts, Gigabot’s portfolio covers a range of printers that bring industrial 3D printing within reach.

Main Benefits of Gigabot

Here’s what makes Gigabot stand out:

- Gigabot 4® offers a build volume up to 30 times larger than typical desktop 3D printers.

- All-metal dual extrusion system supports thermoplastic filaments melting below 320ºC.

- Open-source control powered by a 32bit Ultimachine ArchiMajor board and Klipper firmware on Raspberry Pi.

- GigabotX 2® uses direct-drive pellet extrusion, printing from virgin or recycled pellets, flake, or regrind.

- Extruder screw with a 16:1 compression ratio and NEMA 23 motor enables printing with 3-5mm plastic granules melting below 270ºC.

- Multiple nozzle sizes (0.4, 0.8, 1.75, 3mm) for faster printing and cost savings.

- Modular, upgradable designs with Lifetime Customer Support.

- Starting prices range from $11,800 for DIY kits to $85,000 for the Exabot 4 model.

Technology Behind Gigabot

At its core, Gigabot combines industrial strength components with open-source technology. The printers run on a 32bit Ultimachine ArchiMajor control board paired with Klipper firmware, which operates on a Raspberry Pi. This setup allows users to access controls through the Mainsail interface, whether on the 10” LCD touchscreen or via desktop and mobile web browsers. This blend of hardware and software ensures precision, flexibility, and ease of use, making Gigabot a powerhouse for industrial 3D printing.

Materials and Printing Capabilities

Gigabot printers are designed to handle a wide variety of materials. The Gigabot 4’s all-metal hot end opens the door to printing with high-strength, heat-resistant plastics, recycled filaments, and composites. Meanwhile, the GigabotX 2 line pushes the envelope further by printing directly from plastic pellets, flakes, or regrind. This capability not only supports sustainability but also reduces reliance on filament, speeding up production and cutting costs. It’s a step closer to a circular economy, where reclaimed plastics find new life in innovative manufacturing.

Community and Social Responsibility

re:3D isn’t just about technology; it’s about people and impact. With offices in Austin, Houston, and San Juan, the company actively engages in 3D printing education and community outreach. For every 100 Gigabots delivered, re:3D donates one to a group dedicated to making a difference. This socially driven approach empowers local change-makers and supports new markets, reflecting a commitment to social responsibility that goes beyond business.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 9: Industry, Innovation, and Infrastructure – advancing affordable industrial 3D printing technology.

- SDG 12: Responsible Consumption and Production – promoting recycling and use of reclaimed plastics.

- SDG 13: Climate Action – reducing waste and supporting circular economy principles.

- SDG 4: Quality Education – fostering 3D printing education and community engagement.

- SDG 8: Decent Work and Economic Growth – enabling new markets and empowering local makers.

Looking Ahead with Gigabot

Gigabot continues to push the boundaries of what’s possible in industrial 3D printing. With modular, upgradable designs and a focus on sustainability, it’s not just about printing parts—it’s about creating opportunities. Whether it’s through pioneering reclaimed plastic printing or supporting communities, Gigabot is shaping the future of manufacturing. And with lifetime support and a passionate team behind it, this technology is ready to grow with its users, one layer at a time.