What is the bi0SpaCE Project?

The bi0SpaCE Project, part of Horizon Europe, is a cutting-edge initiative focused on driving sustainable innovation across industries. At its core, the project aims to revolutionize how materials are developed and used, pushing for eco-friendly alternatives that can replace traditional plastics. Noriware, a Swiss startup founded in 2022, has joined this ambitious effort, bringing its expertise in seaweed-based materials to the table. By leveraging advanced material processing technologies, biochemistry, and next-generation material engineering, the project seeks to create packaging and products that are not only sustainable but also high-performing and compatible with existing plastic industry machinery.

Main Benefits of the bi0SpaCE Project

Joining forces with bi0SpaCE offers numerous advantages, especially in the realm of sustainable materials. Here are some key figures and facts that highlight the project’s impact:

- Noriware’s seaweed-based packaging works like plastic but without the environmental harm.

- The project combines expertise from scientists with backgrounds at BASF, Sika, and Migros.

- It uses data analysis and machine learning to identify the best industrial applications for new materials.

- Focuses on creating mechanically functional protective packaging films that fit into existing infrastructure.

- Aims to make eco-conscious choices second nature for everyone, promoting a global shift.

Noriware’s Unique Approach to Sustainable Packaging

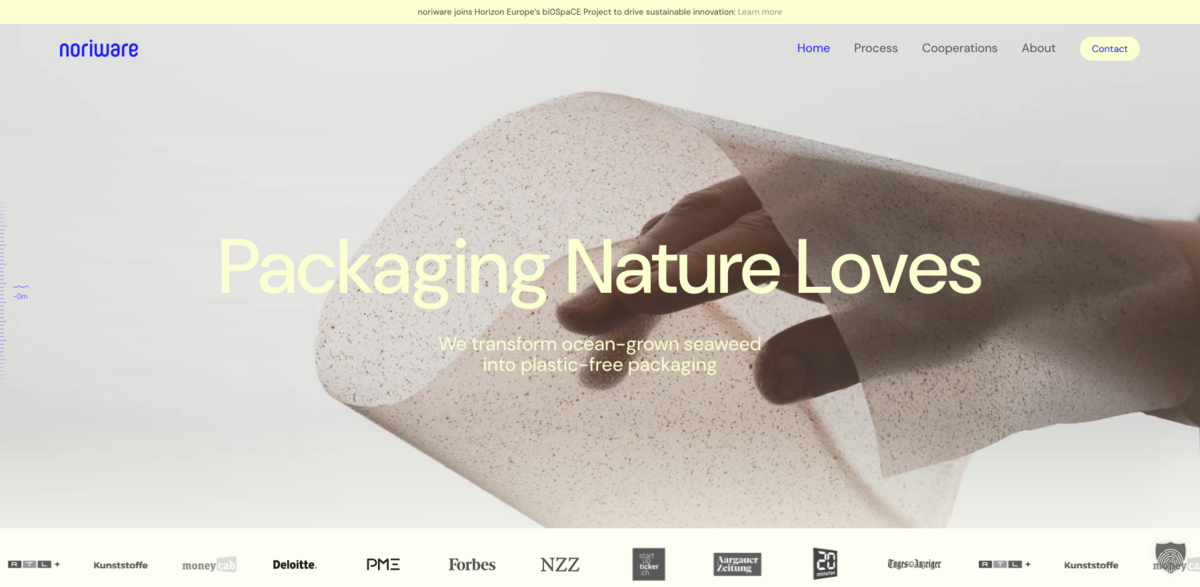

Noriware’s approach is pretty straightforward yet innovative. They develop packaging that nature loves — simple, sustainable, and better for the planet. Their seaweed-based alternatives are designed to replace traditional plastics in packaging and other products, combining sustainability with high-performance functionality. The company’s promise? To commit to change and keep pushing until eco-friendly choices become second nature for all of us. It’s about breaking up with plastic out of pure convenience and taking decisive action to restore the planet’s health.

Advanced Technologies Behind the Innovation

What sets Noriware apart is its blend of biochemistry and next-gen material engineering technologies. They don’t just create new materials; they ensure these materials can be integrated with existing plastic industry machinery and infrastructure. This means their seaweed-based films can be adopted without massive overhauls in production lines. Plus, the team uses data analysis and machine learning to pinpoint exactly where their materials can make the biggest industrial impact. It’s a smart, strategic approach that’s helping to set the pace in the new era of plastic-free materials.

The Team Driving the Change

Behind Noriware’s innovation is a powerhouse team of experienced scientists and industry pros. Many hail from prestigious universities and have worked with major companies like BASF, Sika, and Migros. This blend of academic excellence and real-world industry experience fuels the company’s pioneering strategy. Their combined expertise ensures that the solutions they develop aren’t just theoretical—they’re practical, scalable, and ready to meet today’s environmental challenges head-on.

Project Impact on Sustainable Development Goals (SDGs)

- SDG 12: Responsible Consumption and Production – promoting sustainable packaging alternatives.

- SDG 13: Climate Action – reducing plastic pollution and carbon footprint.

- SDG 14: Life Below Water – protecting marine ecosystems by replacing harmful plastics.

- SDG 9: Industry, Innovation, and Infrastructure – advancing sustainable industrial technologies.

- SDG 15: Life on Land – supporting healthier ecosystems through eco-friendly materials.

The Vision for a Plastic-Free Future

Noriware’s vision is bold yet simple: to enable a global shift where sustainable choices become second nature. Their mission is to unlock the power of seaweed, creating a plastic-free future that’s healthier for the planet. By pioneering sustainable, mechanically functional packaging films, they’re not just imagining a better world—they’re actively building it. Packaging that works like plastic but without the harm. It’s packaging nature loves, and it’s a future everyone can get behind.