What Is the Algica® Project?

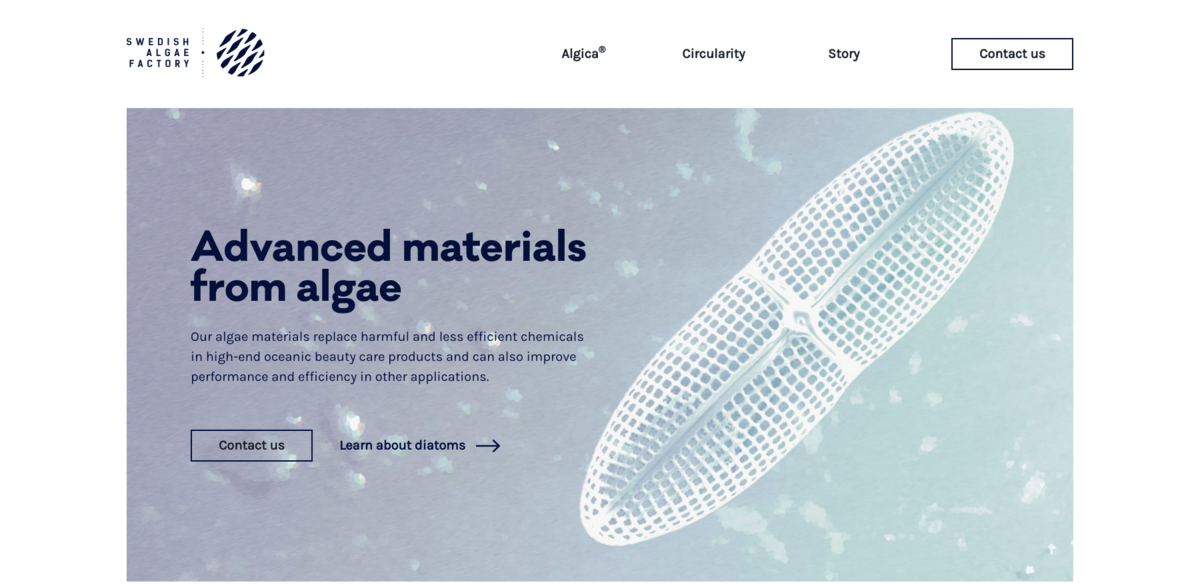

Swedish Algae Factory is pioneering the extraction of a unique nanoporous silica material from algae, branded as Algica®. This high-tech silica shell, derived from diatoms, boasts remarkable light manipulating, absorbing, and releasing properties. Algica® is already making waves as an ocean-safe moisturizer, cleanser, rheology modifier, and anti-pollution agent in skin care products. Beyond beauty care, its UV light blocking traits are currently being tested as a potential UV filter in personal care items. Plus, Algica®’s light manipulating abilities have shown promising results in lab and field tests, boosting solar panel efficiency—a game changer that’s set to hit the market once Swedish Algae Factory’s larger facility is up and running.

Main Benefits and Key Facts

Algica® isn’t just another ingredient; it’s a powerhouse with multiple benefits, all wrapped up in one natural material. Here are some standout facts:

- Production of 1 kg Algica® traps at least 8 kg of CO2, 1 kg of nitrogen, and 0.1 kg of phosphorus.

- Algica® is COSMOS and Natrue approved, ensuring it meets strict organic and natural cosmetic standards.

- Acts as an active marine ingredient, serving as a moisturizer, purifier, detoxifier, sensory enhancer, anti-pollution agent, and SPF booster.

- Replaces several ingredients in one formulation, contributing to more sustainable, high-performing beauty products.

- Uses nutrients and water sourced from a nearby land-based fish farm, embracing a circular economic mindset.

- Focuses on cultivating saltwater species to avoid using scarce freshwater resources.

Innovative Circular Production Process

The production of Algica® is a shining example of circularity in harmony with nature. Swedish Algae Factory’s cultivation process is designed to be 100% circular, converting carbon dioxide, nitrogen, and phosphorus emissions into valuable products. The algae grow using nutrients and water recycled from a nearby fish farm, creating a closed-loop system. After extracting the nanoporous silica shells, the leftover omega-3 oil- and nutrient-rich organic biomass doesn’t go to waste—it’s used sustainably to feed fish, generate energy, and produce eco-friendly fertilizers. This approach not only minimizes waste but also maximizes resource efficiency.

Where Is Algica® Produced?

Algica® is crafted in a state-of-the-art production facility located in Kungshamn, on Sweden’s picturesque west coast. This modern, high-tech site is specifically designed to support sustainable and circular production methods. From cultivation to harvesting and extraction, every step is optimized to preserve the purity and unique natural properties of Algica®. The facility’s focus on sustainability ensures that the entire process aligns with environmental goals while delivering a high-quality product.

EU Project LIFE SUNALGAE: A Solar Innovation

Swedish Algae Factory has secured the prestigious EU LIFE grant for the project LIFE SUNALGAE, marking a significant milestone. This project is the first of its kind to extract and utilize diatom shells on a large scale to enhance solar panel efficiency. By harnessing Algica®’s light manipulating properties, LIFE SUNALGAE aims to boost the performance of solar cells, contributing to greener energy solutions. This innovative application highlights the versatility of Algica® beyond cosmetics, opening doors to sustainable tech advancements.

Project Impact: Linking to the Sustainable Development Goals (SDGs)

- SDG 7: Affordable and Clean Energy – Enhancing solar panel efficiency supports renewable energy adoption.

- SDG 12: Responsible Consumption and Production – Circular production minimizes waste and maximizes resource use.

- SDG 13: Climate Action – Significant CO2 capture during Algica® production helps combat climate change.

- SDG 14: Life Below Water – Sustainable algae cultivation protects marine ecosystems by avoiding freshwater use.

- SDG 15: Life on Land – Use of organic biomass for ecofertilizers promotes sustainable agriculture.

Captivating Oceanic Beauty and Beyond

Millions of years of evolution have gifted diatoms with their porous silica shells, which play a crucial role in producing the oxygen we breathe—every fifth breath, to be exact. But these shells are more than just nature’s oxygen factories. Swedish Algae Factory has cracked the code to harness and refine this natural marvel through a patented cultivation process that preserves its purity and unique properties. The result? An all-natural, non-nano organic material that elevates performance in beauty care products. Algica® acts as a multi-functional ingredient, enhancing moisturization, purification, detoxification, sensory experience, and even boosting SPF protection. It’s a perfect example of how nature’s brilliance can be tapped sustainably to create high-performing, eco-friendly products.