What the Project Is

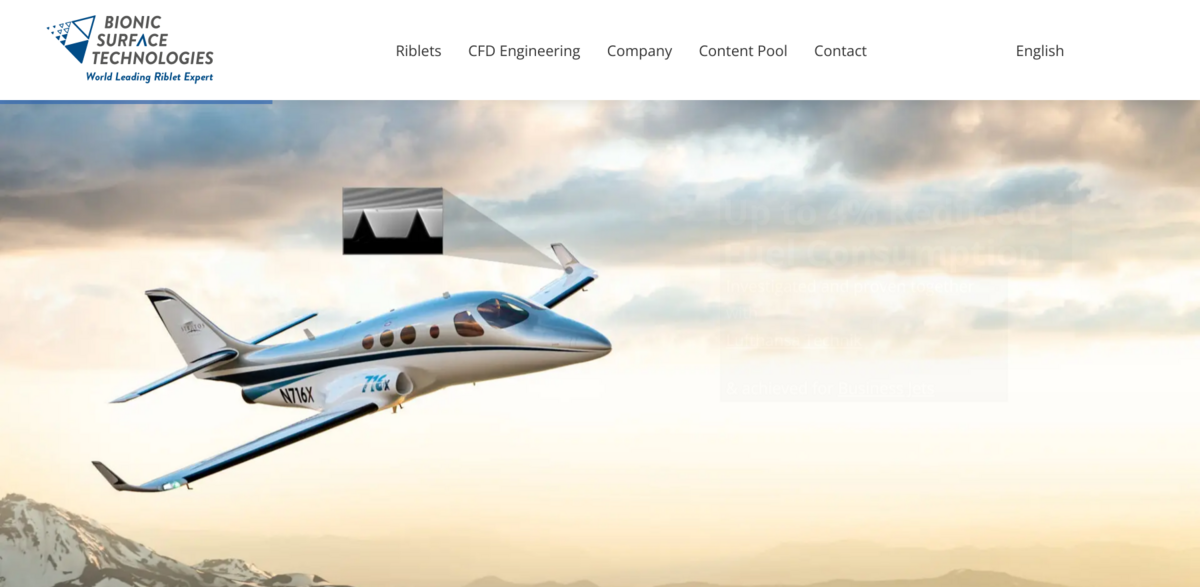

Bionic Surface Technologies is a global research and development company based in Graz, Austria, specialized in the development and optimization of surface textures and the testing and evaluation of these. The company’s focus lies on Riblet surfaces—nano- or micro-structures that reduce fluid-dynamic drag. Inspired directly by the structure of shark skin and its remarkable ability to reduce skin friction, Riblets are micro-scaled surface grooves aligned with the flow direction. This drag reduction system has been investigated and proven together with Lufthansa Technik for aviation applications, and its benefits extend to several other areas such as industrial fans, motorsports, wind power, and many other industrial applications. It is a cutting-edge solution that is integrated into products as paint, foil, or even directly implemented via laser processing into partners’ products… truly a versatile, high-tech development.

Main Benefit

- UP TO 4% REDUCED FUEL CONSUMPTION – Investigated and proven together with Lufthansa Technik for passenger aircraft applications.

- UP TO 3% INCREASED EFFICIENCY – Achieved for industrial fans, leading to improvements in energy management.

- UP TO 0.3S FASTER LAP TIME – Achieved in professional racing, giving a competitive edge in motorsports.

- REDUCE FUEL CONSUMPTION – With Riblets, the cutting-edge drag reduction system provides significant cost savings and improved performance.

- INCREASE POWER OUTPUT – Riblet technology enhances system performance in various technical applications.

Technical Innovation and Research

The innovative use of Riblet structures, directly inspired by the shark skin effect, has been a game changer across the fields of aviation, wind power, and motorsports. These micro-scaled surface grooves reduce fluid-dynamic drag by interacting with the boundary layer of turbulent fluxes, leading to performance gains that are both substantial and measurable. Every application, whether for reducing fuel consumption in aircraft or minimizing noise and boosting energy output in wind turbines, benefits from extensive CFD (Computational Fluid Dynamics) analysis. This type of analysis is a substantial tool of modern engineering and is at the forefront of ensuring that every project is backed by robust, scientific data. It may sound technical, but these benefits translate into clear, pragmatic improvements in energy efficiency and overall performance.

Application Process and Customization

The process begins with a thorough requirement evaluation; engineers complete an initial feasibility study, system design, and execution procedure based on customer input. Following this initial analysis comes a detailed proposal that outlines the project schedule, the work plan, and a precise quote. Once an order is placed, engineers gather all necessary data, ensuring that every factor influencing the project is covered. This stage involves extensive system analyses to craft a comprehensive solution—one that is entirely customized to meet the unique needs of each partner or application. It is a highly collaborative process that maintains a focus on delivering tangible performance improvements with minimal disruption to existing systems.

Production Techniques and Methodologies

The technical application of Riblet surfaces relies on tailored manufacturing methods such as film application, laser processing, and coating techniques. Each method is chosen carefully to suit the final setup and technical parameters of the project in question. This individualized approach means that whether it is a new system design or an upgrade to existing equipment, the integration of Riblet surfaces is seamless and optimized for performance. The process sometimes involves brief, dynamic adjustments and on-the-fly consultations—after all, real-world conditions often require that extra touch of practical insight. The result is a solution that not only meets but exceeds the performance expectations set out in the initial project design.

Operational Excellence Through Maintenance

After the Riblet surfaces are applied, operational readiness is immediate. The facility begins operating with these efficient, state-of-the-art surfaces that pass the test in real-life conditions… and once installed, support doesn’t just end there. Maintenance service is a key part of the project lifecycle, with ongoing consultations provided by expert engineers. This continuous support ensures that the performance gains are sustained over time and that any adjustments or troubleshooting can be handled quickly, fostering a long-term relationship based on efficiency and reliability.

Project Impact

- SDG 7: Affordable and Clean Energy – Reduced fuel consumption and increased efficiency contribute directly to cleaner energy use.

- SDG 9: Industry, Innovation and Infrastructure – Enhanced technological applications in various industries drive sustainable innovation.

- SDG 11: Sustainable Cities and Communities – Improved performance in mobility and industrial applications supports urban sustainability initiatives.

- SDG 13: Climate Action – Lower fuel consumption and decreased emissions help mitigate the impacts of climate change.

Future Horizons and Continued Research

The journey of innovation continues at Bionic Surface Technologies. With an unwavering commitment to research and self- and publicly-funded projects, the advancement of Riblet technology is an ongoing process. Its applications span across several fields that benefit from reduced fluid-dynamic drag—whether it is in cutting-edge aviation, quiet yet powerful wind turbines, or the high-octane world of motorsport. Every project reinforces the promise of sustainable progress, and every consultation underscores that this technology is not just innovative but transformative. With a team of skilled engineers dedicated to continuous improvement and a focus on developing sustainable solutions for future challenges, the landscape of technical applications is set for a dynamic overhaul, one Riblet at a time.